Nhanganyaya

Indasitiri yemotokari yagara iri piyona mukutora matekinoroji ekugadzirisa hunyanzvi, kunyatsoita, uye scalability. Pakati pezvikamu zvaro zvakanyanya kukosha ndeye furemu yemotokari-yakarongeka musana unochengetedza kuchengeteka, kusimba, uye kuita. Sezvo kudiwa kwezvinhu zvisingaremi, kugadzirisa, uye kukurumidza kugadzirwa kuri kuwedzera, vagadziri vari kuwedzera kutendeukira kumarobhoti emaindasitiri kuti vashandure kugadzirwa kwefuremu. Ichi chinyorwa chinoongorora kuti marobhoti ari kugadziridza sei kugadzirwa kwemafuremu emotokari, kubva pakubata zvinhu kuenda kune welding uye kutonga kwemhando, apo ichigadzirisa zvinonetsa uye mafambiro emangwana mune ino simba chikamu.

Chikamu 1: Basa Rakakosha reMotokari Mafuremu muMotokari Dhizaini

Mafuremu emota, anowanzo kunzi chassis, anoshanda sehwaro hwese mota masisitimu. Ivo vanofanirwa kumira kushushikana kukuru, kubata zvinokanganisa, uye kutsigira huremu hwemotokari nevanogara mairi. Mafuremu emazuva ano anogadzirwa achishandisa zvinhu zvemberi zvakaita sesimbi-yakasimba, aruminiyamu alloys, uye kunyange kabhoni fiber composites kuenzanisa simba nekudzikisa huremu.

Nekudaro, kugadzira zvimiro zvakaoma izvi zvinoda kunyatsojeka. Kunyangwe kutsauka kudiki mukumisikidza welding kana chikamu chechikamu chinogona kukanganisa kuchengetedza uye kuita. Maitiro echinyakare echinyakare anonetsekana kuzadzisa kushivirira kwakaomarara kunodiwa neanhasi mota zviyero, zvichigadzira kudiwa kwakanyanya kweautomation.

Chikamu 2: Industrial Robots muFrame Fabrication: Key Applications

2.1 Kubata Kwezvinhu uye Kugadzirira Kwechikamu

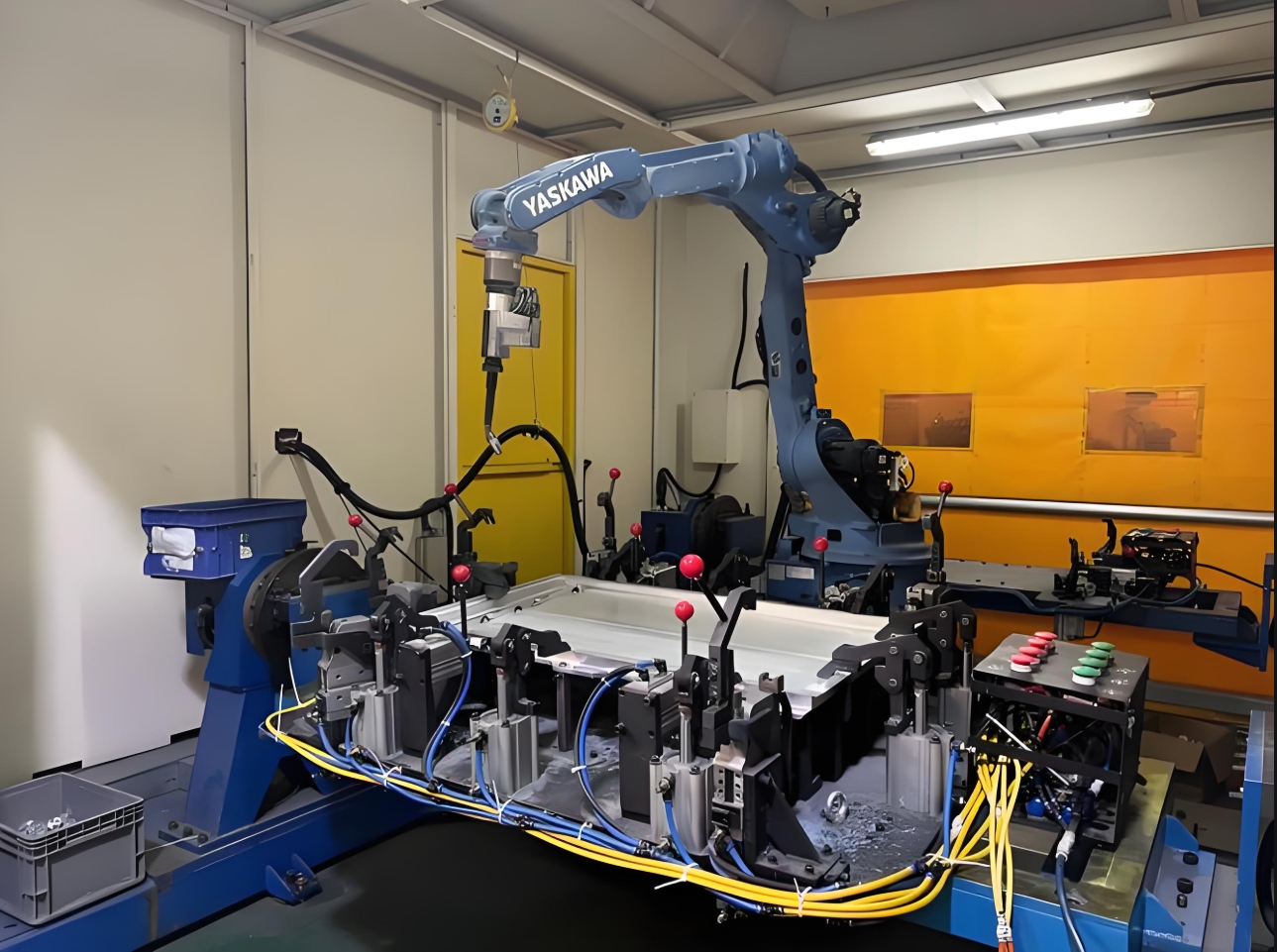

Kugadzirwa kwemafuremu emotokari kunotanga nekugadzirisa zvinhu. Marobhoti eindasitiri akashongedzerwa nemabatiro epamberi uye masisitimu ekuona anokunda pakubata mashizha esimbi akakura, machubhu, uye zvinhu zvakafanogadzirwa. Semuyenzaniso:

- Sheet metal manipulation: Robhoti pre-akachekwa uye kuumba simbi kana aluminium mapepa kuita furemu njanji, crossmembers, uye mabhuraketi ane sub-millimeter kurongeka.

- Composite zvinhu kubata: Marobhoti anodyidzana (cobots) anochengetedza zvinhu zvisingaremi asi zvisina kusimba senge kabhoni fiber, kuderedza tsvina uye kukanganisa kwevanhu.

2.2 Welding uye Joining Technologies

Welding inoramba iri nhanho yakanyanyisa-robhoti mukugadzira furemu. Mazuva ano marobhoti welding masisitimu anoendesa kusingaenzaniswi kunoenderana nezviuru zvemapoinzi weld:

- Resistance spot welding: Multi-axis marobhoti anoita yakakwirira-kumhanya nzvimbo welding pamafuremu esimbi, kuve nechokwadi chekusimba kwemajoini yunifomu.

- Laser welding: Precision marobhoti akashongedzerwa nemisoro yelaser anogadzira majoini asina musono emafuremu ealuminium, kuderedza kukanganiswa kwemafuta.

- Adhesive application: Marobhoti anoisa zvinonamirwa mumapateni akaomarara kusungirira hybrid metal-composite mafuremu, maitiro anenge asingaite kutevedzera nemaoko.

Case Study: Imwe inotungamira yeEuropean automaker yakadzikisa hurema hwewelding ne72% mushure mekutumira boka remarobhoti matanhatu-axis ane adaptive nzira kugadzirisa, inokwanisa kugadzirisa weld parameter munguva chaiyo zvichibva pane sensor mhinduro.

2.3 Gungano uye Kubatanidzwa

Musangano weframe unosanganisira kubatanidza mamoiri ekumisa, mabhureki einjini, uye zvinhu zvekuchengetedza. Marobhoti maviri-maoko anotevedzera hunyanzvi hwevanhu kusungirira mabhaudhi, kuisa mabhushi, uye kurongedza subassemblies. Vision-inotungamirwa masisitimu anovimbisa kuti zvikamu zvakaiswa mukati me ± 0.1 mm kushivirira, yakakosha pakuchengetedza drivetrain kurongeka.

2.4 Kuvimbiswa Kwemhando uye Metrology

Kuongorora mushure mekugadzirwa kwakakosha pakutevedzwa kwemitemo yekuchengetedza. Robotic masisitimu ikozvino anoita:

- 3D laser scanning: Robhoti mepu yese furemu geometries kuona warping kana dimensional kusarongeka.

- Ultrasonic kuongororwa: Automated probes inoongorora weld kutendeseka pasina kukuvadza nzvimbo.

- AI-powered chikanganiso chekuonekwa: Machina ekudzidza algorithms anoongorora mafidhi ekamera kuti aone madiki-akatsemuka kana coating kusawirirana.

Chikamu 3: Zvakanakira zveRobotic otomatiki muKugadzirwa Kweframe

3.1 Kurongeka uye Kudzokorora

Industrial marobhoti anobvisa kusiyana kwevanhu. Irobhoti imwe chete welding sero inogona kuchengetedza 0.02 mm kudzokororwa mukati me24/7 mitsetse yekugadzira, kuve nechokwadi chekuti furemu yega yega inosangana nemagadzirirwo chaiwo.

3.2 Kuwedzerwa Kuchengetedzeka Kwevashandi

Nekuita otomatiki mabasa ane njodzi senge welding pamusoro kana kusimudza zvinorema, vagadziri vataura kuderedzwa kwe60% mukukuvara kwepabasa kune chekuita nekugadzira furemu.

3.3 Kushanda Kwemari

Nepo kudyara kwekutanga kwakakosha, marobhoti anoderedza mitengo yenguva refu kuburikidza:

- 30-50% inokurumidza kutenderera nguva

- 20% yakaderera zvinhu tsvina

- 40% kuderedzwa kwekubhadhara mari

3.4 Scalability uye Flexibility

Modular marobhoti maseru anobvumira vagadziri kuti vakurumidze kugadzirisazve mitsara yekugadzira yeatsva madhizaini. Semuyenzaniso, mafuremu emotokari yemagetsi (EV) ane mabhatiri akavharirwa anogona kubatanidzwa mumasisitimu aripo ane nguva shoma yekudzikira.

Chikamu 4: Kukunda Zvinetso muRobotic Frame Manufacturing

4.1 Material Compatibility Nyaya

Kuchinja kuenda kumafuremu ane zvinhu zvakawanda (semuenzaniso, mahybrids esimbi-aluminum) kunoda marobhoti kuti abate nzira dzakasiyana dzekujoinha. Mhinduro dzinosanganisira:

- Hybrid welding misoro inosanganisa arc uye laser tekinoroji

- Magnetic grippers ekubata zvisina-ferrous simbi

4.2 Programming Complexity

Offline marobhoti programming (OLP) software ikozvino inobvumira mainjiniya kutevedzera uye kukwenenzvera marobhoti workflows nedhijitari, ichicheka yekumisheni nguva inosvika 80%.

4.3 Dambudziko reCybersecurity

Sezvo kugadzirwa kwemafuremu kunowedzera kubatana kuburikidza neIndustrial IoT, vagadziri vanofanirwa kuita encrypted kutaurirana mapuroteni uye yenguva dzose firmware inogadziridza kuchengetedza marobhoti network.

Chikamu 5: Ramangwana reRobotic Frame Manufacturing

5.1 AI-Inofambiswa neAdaptive Manufacturing

Marobhoti echizvarwa chinotevera achakwirisa hungwaru hwekugadzira ku:

- Maturusi ega-calibrate anobva pane ukobvu hwezvinhu

- Kufanotaura uye kutsiva mapfekero emidziyo

- Gadzirisa mashandisirwo emagetsi panguva yekudiwa kwepamusoro

5.2 Kudyidzana kwevanhu-Robhoti

Mabheti ane masimba-akaganhurirwa majoini anozoshanda pamwe chete nematekiniki ekupedzisira magadzirirwo emufuremu, achibatanidza kuita sarudzo kwevanhu nerobhoti chaiyo.

5.3 Sustainable Production

Marobhoti masisitimu achaita basa rakakosha mukuita denderedzwa kugadzira:

- Otomatiki disassembly yemafuremu ekupedzisira-ehupenyu ekudzokorodza

- Precision material deposition kuderedza kushandiswa kwezvinhu

Mhedziso

Kubatanidzwa kwemarobhoti eindasitiri mukugadzirwa kwemotokari kunomiririra zvinopfuura kufambira mberi kwetekinoroji-kunoratidza shanduko yakakosha mumabatirwo nekugadzirwa kwemotokari. Nekuunza humbowo husingaenzaniswi, kunyatsoita, uye kuchinjika, marobhoti masisitimu anogonesa vagadziri kuti vasangane nezvinobuda zvinodiwa zvemotokari dzakachengeteka, dzakareruka, uye dzakasimba. Sezvo AI, masensa epamberi, uye tekinoroji yakasvibira ichiramba ichikura, kuwirirana pakati pemarobhoti neinjiniya yemotokari pasina mubvunzo kunofambisa indasitiri kumazinga asina kumboitika ehunyanzvi.

Kune makambani ane hunyanzvi mumaindasitiri erobhoti, shanduko iyi inopa mikana mikuru yekubatana nevagadziri vemotokari mukutsanangudza remangwana rekufamba-imwe yakanyatsogadzirwa furemu panguva.

Shoko Count: 1,480

Mitemo Yakakosha: Motokari frame marobhoti, marobhoti welding masisitimu, AI mukugadzira, marobhoti anodyidzana, kugadzirwa kwakasimba

SEO Recommendations: Sanganisira meta tsananguro yakanangana ne "automotive frame automation" uye "industrial marobhoti emotokari chassis." Shandisa zvinongedzo zvemukati kune zvinoenderana nenyaya dzezvidzidzo kana mapeji echigadzirwa.

Nguva yekutumira: Mar-26-2025