Kutanga, nzira yekufuridza yekudzivirira gasi

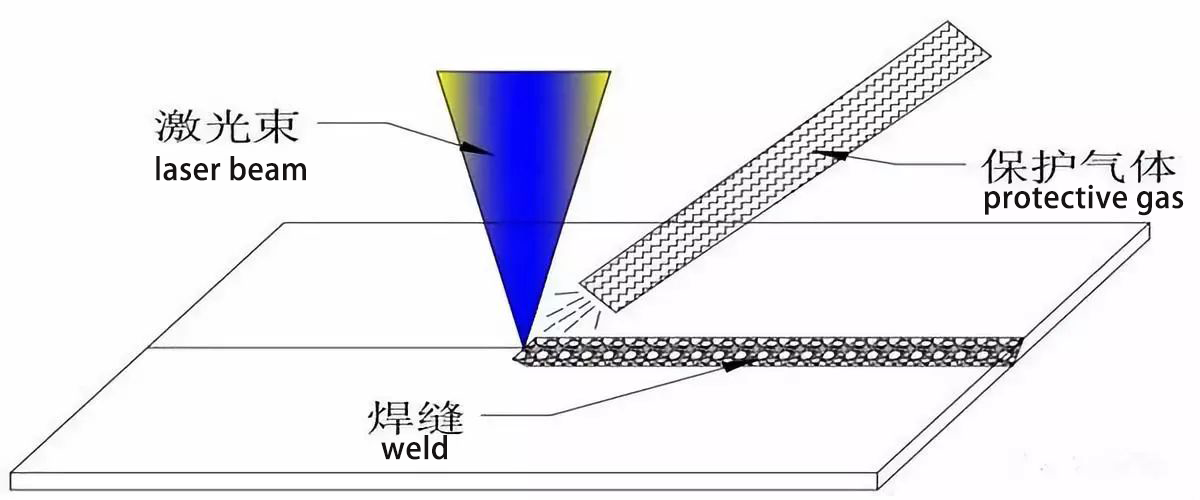

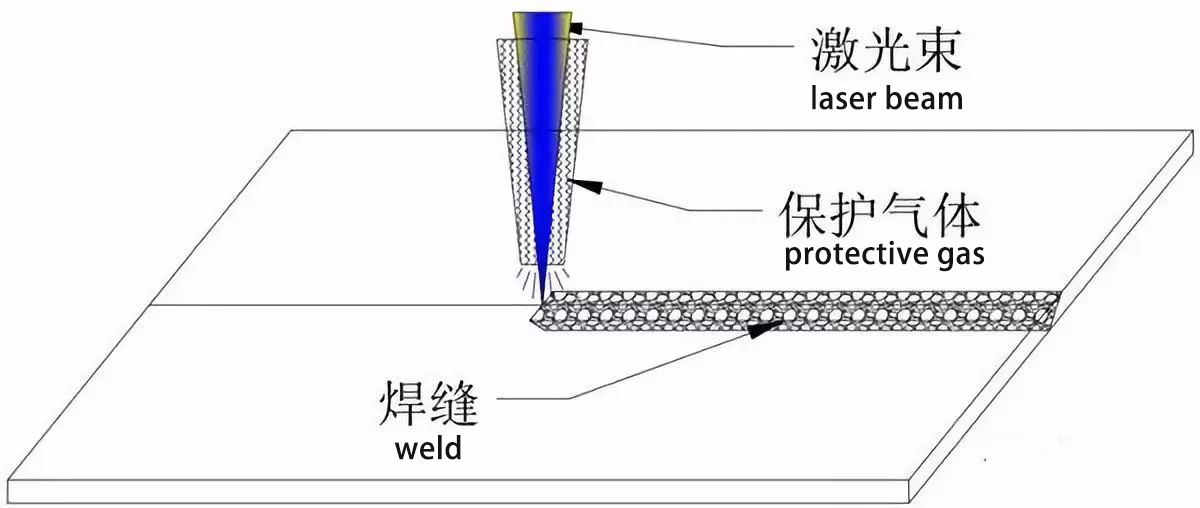

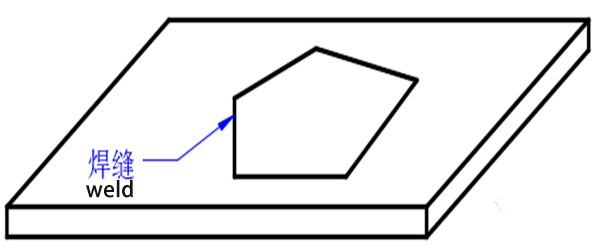

Parizvino, kune nzira mbiri huru dzekudzivirira gasi rekudzivirira: imwe iparaxial side-blowing gasi rinodzivirira, sezvinoratidzwa muMufananidzo 1; Imwe icoaxial kudzivirira gasi.Sarudzo chaiyo yenzira mbiri dzekuvhuvhuta inofungidzirwa mune zvakawanda. Kazhinji, zvinokurudzirwa kushandisa rutivi rwekuvhuvhuta kudzivirira gasi

paraxial inovhuvhuta inodzivirira gasi

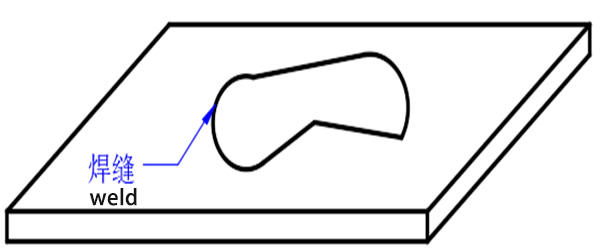

coaxial inovhuvhuta inodzivirira gasi

coaxial inovhuvhuta inodzivirira gasiChechipiri, iyo yekudzivirira gasi inovhuvhuta nzira yekusarudza musimboti

Kutanga, zvinoda kuve pachena kuti iyo inonzi weld "oxidized" inongova zita rinowanzozivikanwa. Nechepfungwa, inoreva maitiro emakemikari pakati pe weld uye zvinokuvadza zvinongedzo mumhepo, izvo zvinotungamira mukuipa kwemhando ye weld. Zvinowanzoitika kuti weld metal iite pamwe neokisijeni, nitrogen uye hydrogen mumhepo pane imwe tembiricha.

Kudzivirira weld kubva ku "oxidized" ndiko kuderedza kana kudzivirira kusangana kwezvinhu zvinokuvadza zvakadaro nesimbi ye weld mune yakanyanya tembiricha mamiriro. Iyi yepamusoro tembiricha mamiriro haisi chete yakanyungudutswa dziva simbi, asi nguva yose muitiro kubva panguva apo weld simbi inonyungudutswa kuti solidification dziva simbi uye tembiricha yayo kunoderedzwa kune imwe tembiricha pazasi.

Chechitatu, tichitora muenzaniso.

Semuenzaniso, titanium alloy welding, kana tembiricha iri pamusoro pe300 ℃ inogona kukurumidza kutora hydrogen, inopfuura 450 ℃ inogona kukurumidza kusveta okisijeni, kupfuura 600 ℃ inogona kukurumidza kutora nitrogen, saka titanium alloy welding seam mushure mekusimba uye kudzikiswa kwekushisa kusvika 300 ℃ pazasi danho iri rinofanira kuva rinoshanda kudzivirira, kana zvisina kudaro, richava rinoshanda kudzivirira.

Kubva pane tsananguro iri pamusoro haina kuoma kunzwisisa, kuchengetedzwa kwegasi rinoputika hakungodi panguva yakakodzera kuchengetedza weld yakanyungudutswa dziva, zvakare inofanirwa kunge yakasungirirwa nzvimbo yakaomeswa yedziviriro, saka kazhinji tora paraxial inoratidzwa mumufananidzo 1 divi rinodzivirira gasi, nekuti nzira iyi inoenderana nedziviriro yekudzivirira kweiyo coaxial nzira yekudzivirira yenhamba 2, iyo nzvimbo yekudzivirira yakawedzera zvakanyanya.

Paraxial side inovhuvhuta yeinjiniya maapplication, hazvisi zvese zvigadzirwa zvinogona kushandisa nzira yekudivi shaft yekufuridza gasi yekudzivirira, kune zvimwe zvigadzirwa, inogona chete kushandisa coaxial yekudzivirira gasi, chaiyo inodiwa kubva kune chigadzirwa chimiro uye fomu rekubatanidza rakanangana sarudzo.

Ina, yakananga kudzivirira gasi kuvhuvhuta modhi sarudzo

1. Sight welds

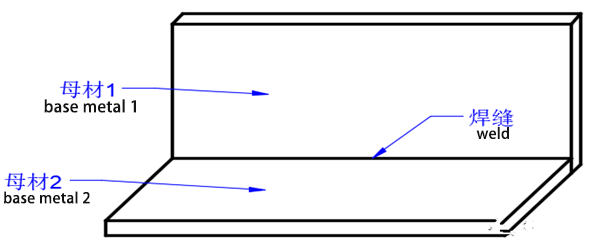

Sezvinoratidzwa muMufananidzo 3, chimiro cheweld chechigadzirwa chakatwasuka, uye chimiro chejoinhi chinogona kunge chiri chebutt joint, lap joint, negative corner joint kana overlapping welding joint. Kune rudzi urwu rwechigadzirwa, zviri nani kutora rutivi rweparutivi rwunofuridza nzira yekudzivirira gasi sezvakaratidzwa mumufananidzo 1.

2. Flat yakavharwa graphic weld

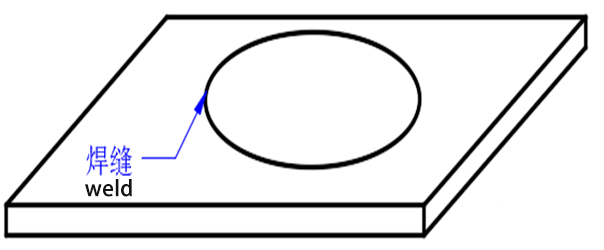

Sezvinoratidzwa mumufananidzo 4, iyo weld chimiro chechigadzirwa indege circumferential chimiro, ndege multilateral chimiro, ndege yakawanda-segment mutsara chimiro uye mamwe akavharika maumbirwo. Iyo yejoint form inogona kuve butt joint, lap joint, overlapping welding zvichingodaro. Kune rudzi urwu rwechigadzirwa, zviri nani kutora iyo coaxial inodzivirira gasi modhi inoratidzwa muMufananidzo 2.

Kusarudzwa kwegasi rinodzivirira kunokanganisa zvakananga kunaka kwewelding, kushanda zvakanaka uye mutengo wekugadzira, asi nekuda kwekusiyana kwezvinhu zvewelding, mune chaiyo welding process, kusarudzwa kwegasi rewelding yakanyanya kuomarara, inoda kutariswa kwakadzama kwewelding zvinhu, welding nzira, chinzvimbo chewelding, pamwe nezvinodiwa zvewelding mhedzisiro, kuburikidza nemiedzo yewelding kuti usarudze iyo yakanyanya kufanira kukwenenzvera gasi.

Kunobva: Welding Technology

Nguva yekutumira: Sep-02-2021