Pane zvikonzero zvakawanda nei robhoti yekushongedza ichipisa iyo yekubata tip panguva yekugadzira welding process. Semuyenzaniso, chiitiko chepamusoro chekugara kuchitsiviwa kwetipi yekubata ndeichi: kupfeka kweiyo yekubata tip yekubuda kunoita kuti waya yekudyisa ienderere mberi, uye iyo chaiyo welding track inochinjirwa, ndiko kuti, TCP point position shift, Lead kune welding defects senge welding offset kana welding leakage.

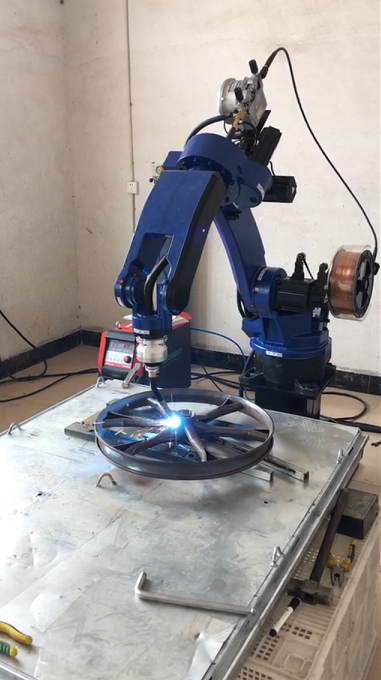

Kuongororwa kweMatambudziko Anokonzerwa neWelding Robot Kupisa Kubata Tip

1. Chikonzero chekukundikana kwekubatana tip pachayo

Kupfeka kweiyo yekubata tip yewelding robhoti pachayo kunokonzerwa nekupfeka pakubuda kwetipi yekusangana nekuda kwekupokana kwekuenderera mberi kwekudya kwewaya pasi pekukwira kwekushisa kweiyo yekubata tip. Munguva yekushanda kwewelding yerobhoti yekushongedza, zvikanganiso zvecalibration zvinowanzoitika uye zvinokanganisa kugadzirwa. kunyatsoshanda. Panguva ino, iwe unofanirwa kuyedza kudzikisira tembiricha yetipi yekubata, kusanganisira kuumbwa kweiyo yekubata tipi uye kugadzirisa kweiyo yekubata tip chimiro. Zvinyorwa zvetipi yekubatana: ndarira, mhangura tsvuku, pakati payo chromium zirconium mhangura ndiyo yakanakisisa; kunyange kuwedzera ceramic zvikamu kune yekubata tip inogona kuwedzera kupfeka kuramba. Yechitatu ndeyekugadzirisa kurongeka kwetipi yekusangana. Nekuda kwekurongeka kwemidziyo yekugadzirisa kana mamwe matambudziko, iyo yemukati gomba kupera uye concentricity yetipi yekusangana haina kukwana.

2. Iyo arc haina kugadzikana, zvichiita kuti arc apise kumashure

Chimwe chezvikonzero zvinosanganisira kudzima kwakashata kwearc, kusagadzikana kwearc, kushata waya yekudyisa, kuchena kweiyo workpiece pamusoro, nezvimwewo, asi hazvireve kukanganisa kushanda kwetipi yekusangana pachayo. Panguva ino, kutadza kwewelding kunenge kwakabatana nehunhu hwesimba remagetsi sosi uye kunaka kwewaya yewelding. , waya yekudyisa maitiro, waya yekudyisa hose uye yekubata nozzle chimiro dhizaini. Kana iyo welding wire uye iyo conductive point mune yekusangana tip inogara ichichinja, hupenyu hwayo ihafu chete iyo iyo iyo conductive point yakagadzikana.

3. Zvikonzero zvekugadzirisa waya uye kupera kwepamusoro

Iyo welding waya yewelding robhoti inowanzoiswa mudhiramu kana ndiro, uye zvakare ine mabhura kana mbabvu, saka inogona kukanganisa kubata pakati pewaya yewelding uye yekubata tip. Kana iro robhoti welding iri welding, iyo yekubata tipi inofanirwa kuve yakadzikama conductive pasi penzvimbo Inopa kushoma kukweshera. Upenyu hwekubata tip yetsvina welding wire hunogona kungove chikamu chimwe muzvitatu chekushandisa kwakachena welding waya; kutonga kunaka kwewaya yewelding, dhigirii rekudzoreredza kushushikana kwewaya yewelding, kuita ndiko kutwasuka kwakaita: mhinduro yebvunzo ndeye 50mm kubva kumberi kweacrobatic welding gun nozzle, kana waya yewelding inogona kungopeta yega, kukotama kumberi zvinoreva kuti waya welding yakanyanya kupfava, kukotama kuseri kunoreva kuomarara, iyo yakaomesesa welding inodhura; chechipiri, kana waya yekudyisa hose kubva pawaya yekudyisa kusvika kune welding pfuti yakakotama ichaitawo kuti waya yewelding igonyereke. camber.

Nguva yekutumira: Kubvumbi-24-2022