Nhanganyaya

Chikamu chekugadzira mota chiri kuramba chichivimba nemarobhoti eindasitiri kuti awane kunyatsoita, kunyatsoita, uye kuenderana mukugadzira. Pakati peanonyanya kukosha maapplication ndeye welding yezvikamu zvemotokari, kunyanyaekisi(inozivikanwawo semaekisi emotokarikanamaekisi emota), izvo zvakakosha pakugadzikana kwemotokari, kutapurirana kwemagetsi, uye kutakura mutoro. Ichi chinyorwa chinoongorora kuti mberi seirobotic welding systemsvari kushandura kugadzirwa kwemaaxles uye zvimwe zvikamu zvemotokari, uku vachiratidzira mazwi makuru mune ese ari mavirizvikamu zvemotokariuyewelding marobhoti.

Chikamu 1: Makiyi Emotokari Zvikamu mu Focus

Kugadzira mota kunosanganisira magungano akaomesesa, ane zvinotevera zvikamu zvakakosha pakushanda kwemotokari. Heano iwopamusoro 5 motokari chikamu keywordszvinoenderana nehurukuro iyi:

- Ekisero (Ekisero yeMota/Ekisero yeMota)

Maekisi ari pakati pechitima chemotokari, mavhiri ekubatanidza uye kutsigira huremu hwemotokari. Precision welding inovimbisa kutendeseka kwechimiro uye kusimba. - Suspension Systems

Zvikamu zvakaita semaoko ekudzora uye ma struts anoda wakasimba welding kuti amire kushushikana kwemugwagwa. - Drivetrain Components

Zvikamu zvakadai sezvivakwa zvakasiyana-siyana uye mabheti ekufambisa anovimba nepamusoro-simba welds. - Chassis Frames

Iyo musana wemotokari, chassis mafuremu anoda inowirirana weld mhando yekuchengeteka. - Exhaust Systems

Complex welds pane manifolds uye pombi dzinofanira kuramba kupisa uye ngura.

Pakati peizvi,ekisero weldinginomira kunze nekuda kwekuoma kwayo kwehunyanzvi uye kukanganisa pakuita kwemotokari.

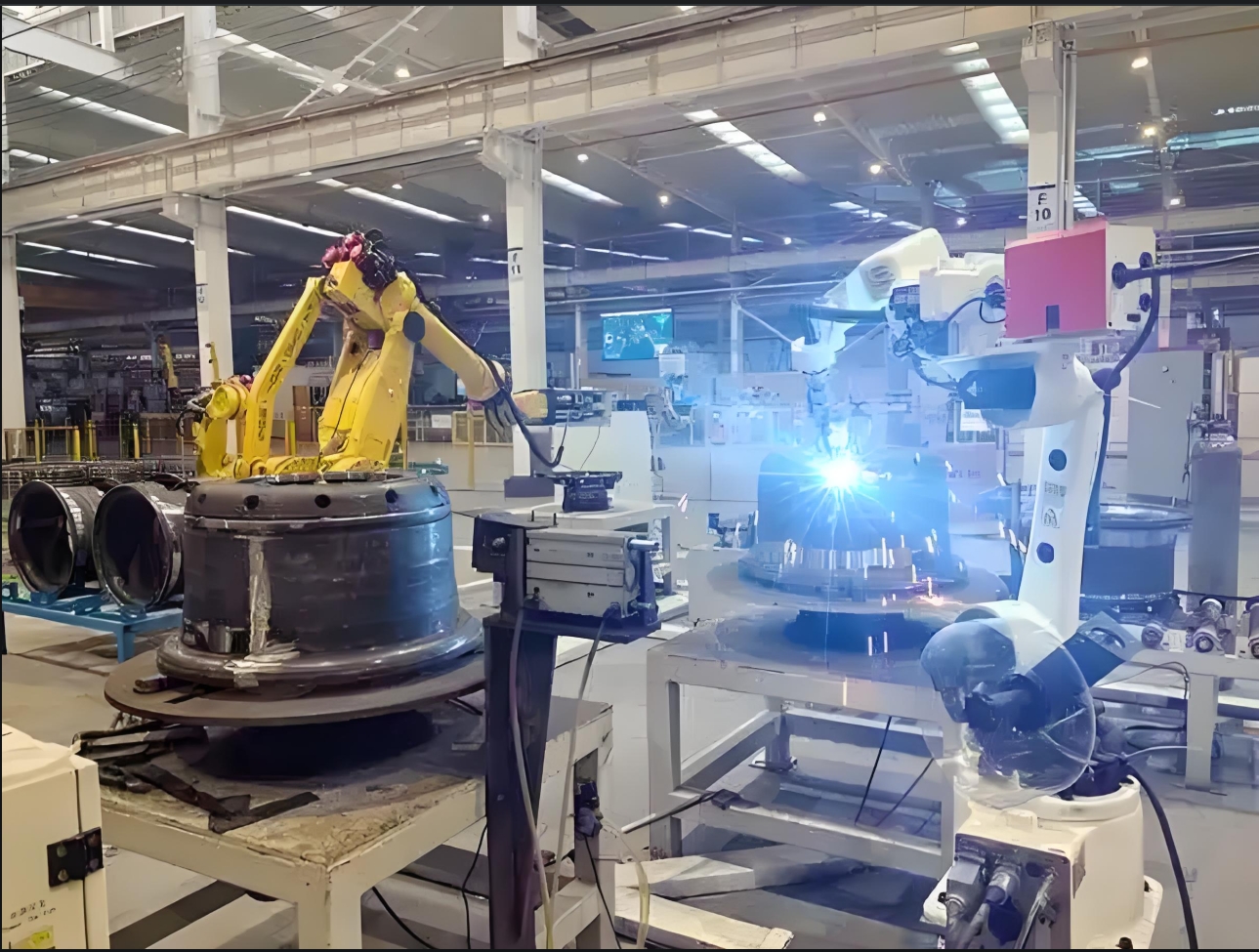

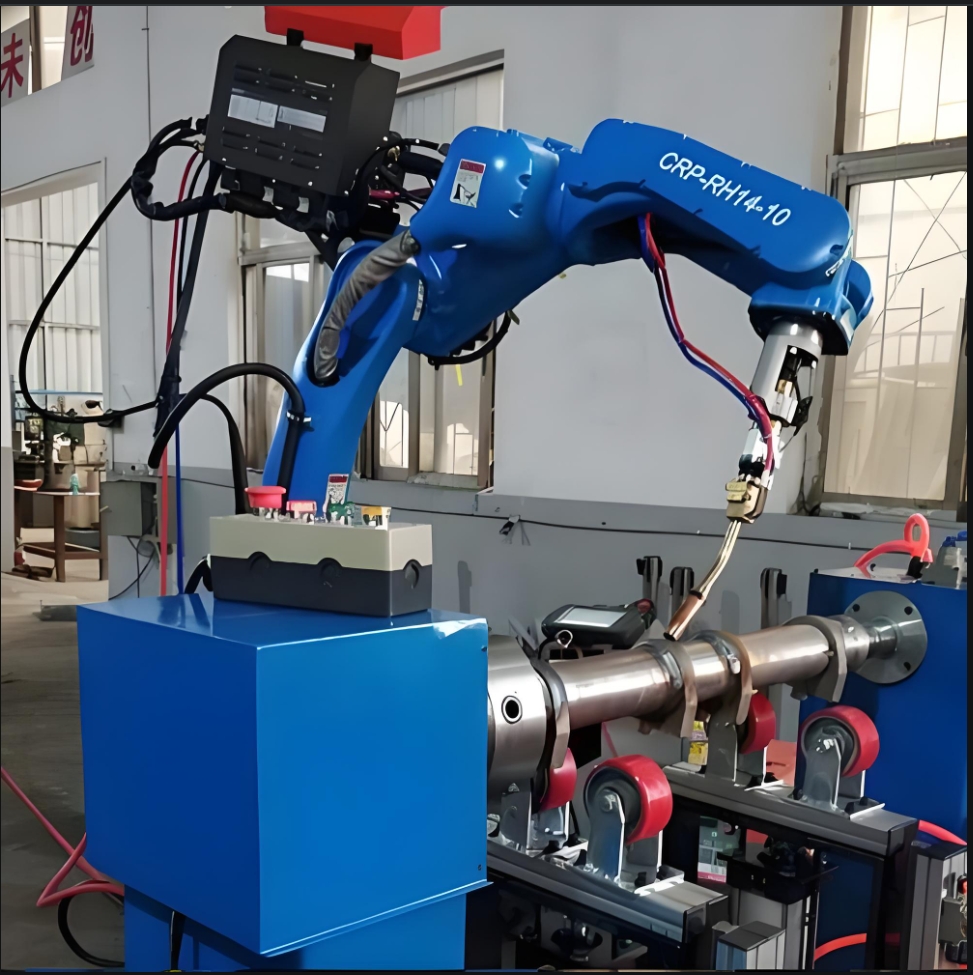

Chikamu 2: Industrial Welding Robots: Technology uye kugona

Mazuvanorobotic welding systemsbatanidza matekinoroji epamusoro kuti asangane nezviyero zvemotokari. Pazasi panepamusoro 5 welding robhoti keywords:

- Automated Welding

Automation inovimbisa kudzokorora uye inoderedza kukanganisa kwevanhu mukugadzirwa kwepamusoro-vhoriyamu. - Arc Welding (MIG/TIG)

Inofarirwa kugadzirwa kweaxle nekuda kwekupinda kwakadzika uye kuumbwa kwakasimba kwemajoini. - Laser Welding

Inoshandiswa kune yakakwirira-chaiyo mabasa, senge welding yakatetepa axle shafts ine kushoma kukanganisa. - Spot Welding

Yakanakira kujoinha anopindirana simbi mashiti mukumiswa kana chassis zvikamu. - Marobhoti Anoshanda (Cobots)

Wedzera kuchinjika munzvimbo dzakasanganiswa-yekugadzira, kushanda pamwe chete nenyanzvi.

Aya matekinoroji anogonesa vanogadzira kuitazero-defect weldingpazvikamu zvakakosha semaekisi.

Chikamu 3: Welding Axles ane Industrial Robots: Maitiro uye Benefits

Danho 1: Dhizaini uye Kuronga

Axle welding inotanga neCAD/CAM simulations kukwirisa nzira dzeweld. Robhoti akarongerwa mafambiro e-multi-axis, kuve nechokwadi chekuwana kune yakaoma geometries.

Danho Rechipiri: Kugadzirira Zvinhu

Maekisi anowanzo gadzirwa kubva kune yakakwirira-simba simbi kana aruminiyamu alloys. Marobhoti masisitimu pre-akachena nzvimbo uye masimbi ezvikamu kuti aderedze kusarongeka.

Nhanho 3: Welding Execution

- Arc Welding: Inoshandiswa kune gobvu axle dzimba, kuve nechokwadi chakadzika, yunifomu seams.

- Laser Welding: Inoshandiswa kune chaiyo majoini mune lightweight axle dhizaini.

- Seam Tracking Sensors: Bvisa kusawirirana kwezvinhu munguva chaiyo.

Zvakanakira Robotic Axle Welding:

- Enhanced Strength: Consistent welds inoderedza kupera simba.

- Faster Cycle Times: Robhoti inoshanda 24/7, inosimudzira kuburitsa.

- Kuchengeta Mari: Kuderera kwezvirafu mitengo uye kuderedzwa kwemari yebasa.

- Safety: Inobvisa kuratidzwa kune pfari uye utsi hwevashandi.

Chikamu 4: Indasitiri Maitiro Kugadzira Robotic Welding

- AI-Powered Quality Control

Machine yekudzidza algorithms inoongorora weld kutendeseka, mureza kuremara munguva chaiyo. - Lightweighting Demands

Marobhoti anochinjika kune weld advanced zvinhu senge aruminiyamu-kabhoni macomposites emagetsi mota (EV) axles. - IoT Integration

Marobhoti akangwara anoendesa data rekuita kune epakati masisitimu ekufungidzira kugadzirisa. - Sustainability

Simba-inoshanda welding maitiro anoderedza kabhoni tsoka.

Aya maitiro anomirarobotic welding systemssezvakakosha mumafekitari emotokari emazuva ano.

Chikamu 5: Matambudziko uye Magadzirirwo

Nepo robhoti welding ichipa mabhenefiti akakura, matambudziko anoramba aripo:

- High Initial Investment: Yakaderedzwa neyenguva refu ROI kubva pakuwedzera kubereka.

- Complex Programming: Yakarerutswa kuburikidza nemushandisi-inoshamwaridzika nzvimbo uye kunze kwepamhepo simulation maturusi.

- Material Variability: Yakaiswa neadaptive sensors uye AI-inotyairwa zvigadziriso.

Kune axle welding, kubatana nevane ruzivomaindasitiri marobhoti vagadziriinovimbisa zvakagadzirirwa mhinduro.

Mhedziso

Iyo welding yemidziyo yemotokari senge maaxles inoratidza simba rekushandura remarobhoti emaindasitiri. Nekushandisa simbaautomated welding,arc welding,uyelaser weldingmatekinoroji, vagadziri vanowana kurongeka kusingaenzaniswi uye kugona. Sezvo indasitiri yemotokari inoshanduka-kunyanya nekukwira kweEVs-robotic welding systemsicharamba iri pakati pekugadzira yakasimba, yepamusoro-inoshanda zvikamu. Kune mabhizinesi ari kutsvaga kugadzirisa mitsara yavo yekugadzira, kudyara mune advanced welding marobhoti haisi sarudzo chete asi chinhu chinodiwa.

Keywords: Axle, Vehicle Axle, Suspension Systems, Drivetrain Components, Chassis Frames; Automated Welding, Robotic Welding Systems, Arc Welding, Laser Welding, Spot Welding.

Nguva yekutumira: Kubvumbi-02-2025