Indasitiri yemotokari inofanana nehunyanzvi, inoda kunyatsojeka, kumhanya, uye kuvimbika mukugadzira chikamu. Pakati pezvikamu zvakakosha zvemotokari, masisitimu ekupedza simba - kunyanya mapombi anopedza simba - anoita basa rakakosha mukuita kwemotokari, kudzora kuburitsa, uye kuderedza ruzha. Sezvo vagadziri vanoyedza kusangana neakaomesesa emhando zviyero uye zvinangwa zvekugadzira, marobhoti ewelding akabuda semidziyo yakakosha mukugadzira masisitimu emhepo. Ichi chinyorwa chinoongorora kuti marobhoti welding masisitimu, akabatanidzwa sei nepamusoro pekumisa michina sengerotary tilt positionersuyecustomized fixtures, vari kushandura kugadzirwa kwepombi dzemagetsi emhepo, kukwidziridza kushanda zvakanaka, kusachinja-chinja, uye kunaka kwechigadzirwa kusvika padanho risati ramboitika.

1. Kuoma kweExhaust Pipe Manufacturing

Mapombi eexhaust anoiswa pasi pemamiriro akanyanya, anosanganisira tembiricha yakakwira, magasi anoparadza, uye ma mechanical vibrations. Kumira nezvinetso izvi, zvinowanzogadzirwa kubva kusimbi isina tsvina kana simbi yakanyungudutswa uye inoda musono, isina mhepo welds mukati meiyo yakaoma geometries. Traditional manual welding maitiro anowanzo kunetseka kuchengetedza kuenderana mumashandisirwo akadai, zvichitungamira kune hurema hwakaita seporosity, isina kukwana fusion, kana kukanganisa.

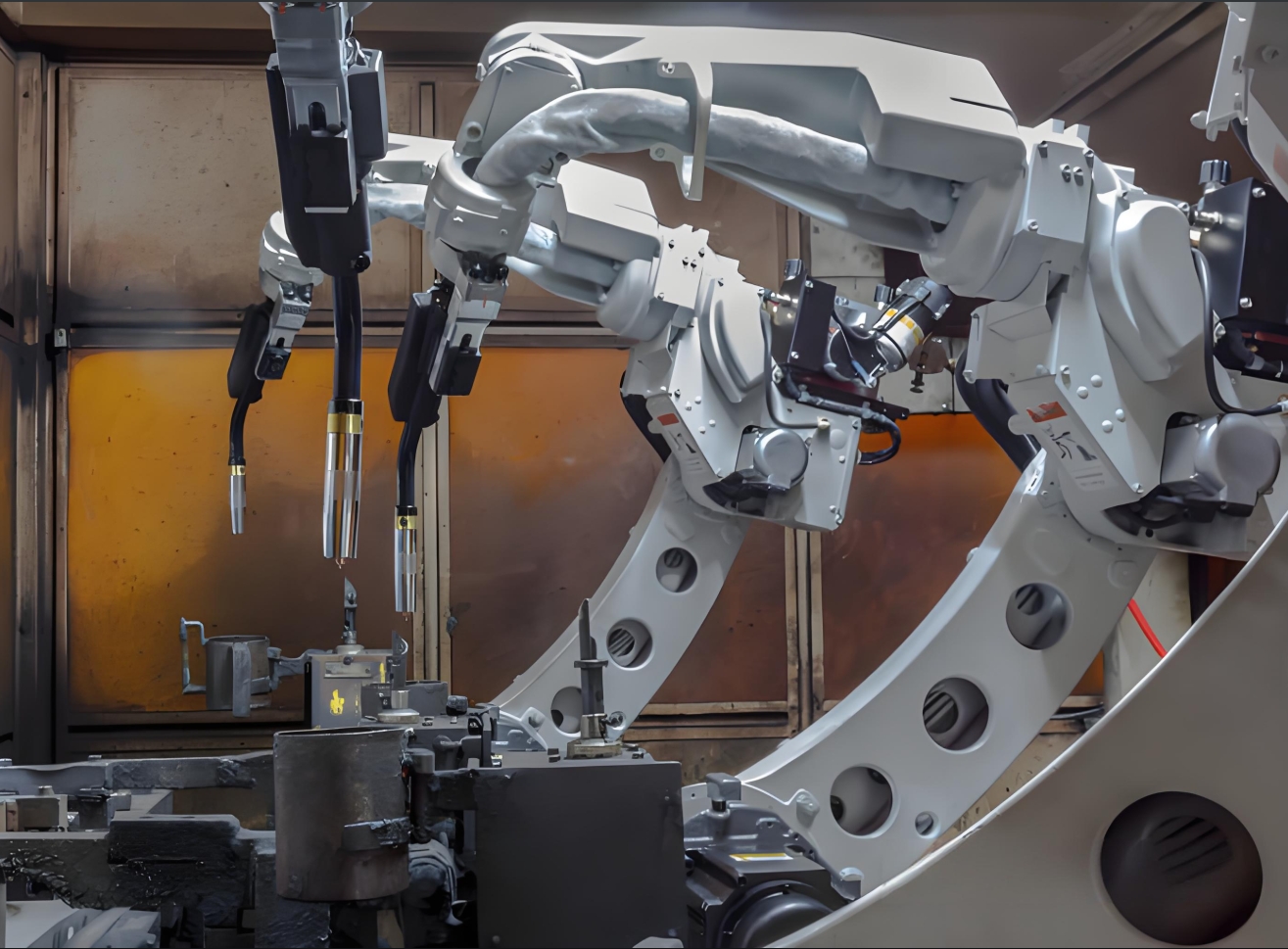

Welding marobhoti, zvisinei, anokunda mukubata izvi zvakaomarara. Yakashongedzerwa neakawanda-axis kutaura uye yakawiriraniswa nechaiyo yekumisikidza masisitimu, ivo vanounza mawelds asina chikanganiso pane yakakomberedzwa nzvimbo, flanges, uye majoini-yakakosha pakuona exhaust system kutendeseka.

2. Robotic Welding in Action: Key Applications for Exhaust Pipes

2.1 Tube-ku-Flange uye Tube-to-Muffler Welding

Exhaust masisitimu anosanganisira akawanda maficha, anosanganisira mapaipi, catalytic converters, resonators, uye mufflers. Marobhoti welding masisitimu anogadzirisa kubatanidzwa kwemachubhu kune flanges kana muffler housings, kuve nechokwadi chekupinda kweyunifomu uye kuderedza kupisa-kukanganisa nzvimbo (HAZ). Somuenzaniso, a6-axis articulated robhotiinogona kufamba ichitenderedza denderedzwa repombi, ichichengetedza makona etochi akakwana uye kumhanya kwekufamba kunyangwe panzvimbo dzakakomberedzwa.

2.2 Laser Welding yeTin-Walled Components

Mapombi epombi emazuva ano anowanzo ratidza madhizaini akatetepa kuti aderedze uremu asi achichengetedza simba. Laser welding marobhoti, ane simba rawo rakawanda uye yakamanikana weld seams, inodzivirira warping uye kuchengetedza zvinhu. Izvi zvinonyanya kubatsira kune Stainless simbi exhaust masisitimu, uko kurongeka kwakakosha.

2.3 Multi-Pass Welding yeMajoini akakora

Kune zvinorema-duty exhaust masisitimu mumotokari dzekutengesa, marobhoti gasi simbi arc welding (GMAW) masisitimu anoita ma-multi-pass welds kuvaka majoini akasimba pakati pepombi dzakakomberedzwa nemadziro nemabhuraketi. Adaptive welding algorithms inogadzirisa ma paramita munguva chaiyo kuti agadzirise kusiyana kwezvinhu.

3. Kuvandudza Flexibility neRotary Tilt Positioners

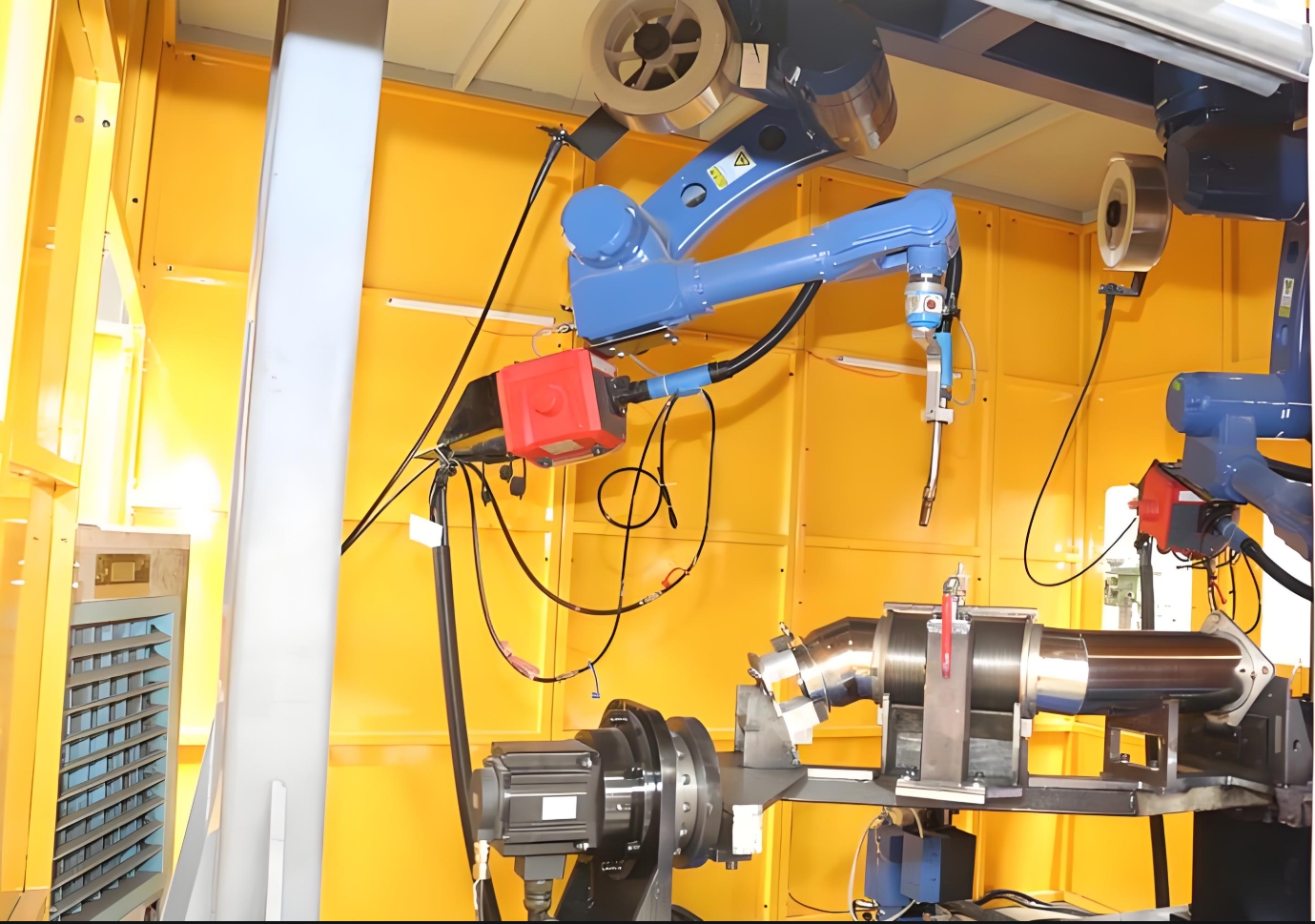

Kubudirira kwerobhoti welding cell kunotsamira pakubatana kusina musono pakati perobhoti neworkpiece.Rotary tilt positionersakakosha mukuita uku, achigonesa 360-degree kutenderera uye kurereka kwepombi dzemhepo panguva yewelding. Benefits zvinosanganisira:

- Optimal Joint Accessibility: Iyo positioner inodzoreredza pombi kuti iratidze weld seam munzvimbo yakatsetseka kana yakachinjika, kurerutsa marobhoti kuronga uye kuderedza kutenderera nguva.

- Yakaderedzwa Repositioning: Nekugadzirisa zvine simba iyo workpiece, iro robhoti rinogona kupedzisa akawanda welds mune imwechete setup, kuderedza kusaita nguva.

- Yakavandudzwa Ergonomics: Vashandi vanoremedza / kurodha zvinhu apo robhoti rinopisa, richiwedzera kubuda.

Semuyenzaniso, mbiri-chiteshi chinzvimbo inobvumira imwe pombi kuti isimbiswe nepo inotevera ichiremerwa, ichiwana pedyo-inoenderera kugadzirwa.

4. Precision Fixturing: The Backbone of Consistency

Customizedwelding zvigadzirisozvakakosha pakubata zvinhu zvinopedza simba mukurongeka chaiko panguva yerobhoti welding. Zvinonyanya kukosha zvekugadzira zvinosanganisira:

- Clamping Mechanisms: Pneumatic kana hydraulic clamps inochengetedza pombi, flanges, uye mabhuraketi pasina kusvibisa nzvimbo.

- Modularity: Kurumidza-shanduko zvigadziriso zvinogara akasiyana pombi madhayamita kana masisitimu, akanakira musanganiswa-modhi kugadzirwa.

- Thermal Management: Fixtures dzakagadzirwa kubva kuzvinhu zvinodzivirira kupisa zvinomira kuratidzwa kwenguva refu kune welding arcs.

Zvigadziriso zvepamberi zvinosanganisa masensa kuti aone kuiswa kwechikamu kusati kwatanga, kubvisa kukanganisa kurongeka.

5. Quantifying Efficiency Gains

Kugamuchirwa kwemarobhoti welding masisitimu mukugadzira pombi yepombi kunopa kuvandudzwa kunoyerwa:

- Kuderedzwa Kwenguva Yekutenderera: Robhoti yeMIG welder inogona kupedzisa circumferential weld mumasekonzi makumi matanhatu, ichienzaniswa ne180+ masekonzi ekugadzira manyore.

- Higher Uptime: Marobhoti anoshanda 24/7 ane kushoma kuderera, achiwedzera gore negore kubuda ne30-50%.

- Material Savings: Precise parameter control inoderedza spatter uye rework, kudzikisa mari inodyiwa ne15-20%.

Semuenzaniso, Tier-1 mota mutengesi akashuma a40% kuwedzera kwekuwedzeramushure mekutumira masero erobhoti ane synchronized positioners yekusangana kwekupedza.

6. Kusimudza Hunhu kuMotokari Mitemo

Robotic welding inovimbisa kuteedzera mota mhando mabhenji akadai seIATF 16949:

- Kudzokorora: Marobhoti anodzokorora nzira dze weld ne ± 0.1 mm kurongeka, kubvisa kusiyana kwevanhu.

- Defect Detection: Yakabatanidzwa yekuona masisitimu kana arc monitoring sensors inoona zvisizvo pakati pekuita, zvichikonzera kururamisa nekukurumidza.

- Zvinyorwa: Otomatiki masisitimu anogadzira anoteedzera weld matanda, akakosha pakuongorora uye kuyeuka.

Post-weld inspections inoratidza kuti marobhoti masisitimu anoderedza porosity uye crack rates nepamusoro pe90% zvichienzaniswa nemaitiro emaoko.

7. Sustainability uye Ramangwana Trends

Vagadziri vemotokari vari kuwedzera kuisa pamberi pekuchengetedza. Robotic welding inotsigira shanduko iyi ne:

- Kuderedza Kushandiswa Kwemagetsi: Inoshanda arc-nenguva uye yakagadziridzwa mafambiro nzira dzakadzikisa simba rekushandisa.

- Kuderedza Waste: Higher first-pass goho rates inoderedza zvimedu.

- Kugonesa Lightweighting: Precision welding inofambisa kushandiswa kwezvinhu zvepamberi, zvitete pasina kukanganisa kusimba.

Kutarisa mberi,AI-inotyairwa welding marobhotiichakwidziridza muchina kudzidza kuti uzvigadzirise wega paramita yezvinhu zvitsva, ukumarobhoti anodyidzana (cobots)ichabatsira vashandisi mukugadzira diki-batch.

Mhedziso

Munzvimbo yepamusoro-soro yekugadzira mota exhaust system, marobhoti emagetsi-akawedzerwa nevakangwara vanomira uye zvigadziriso-zvinomiririra iyo yepamusoro yeinjiniya chaiyo. Nekuita otomatiki akaomesesa welding mabasa, aya masisitimu anogonesa vagadziri kuti vakwanise kukurumidza kutenderera nguva, hunhu husingaite, uye kugadzirwa kunotyisa. Sezvo mirau yekuburitsa kubuda kwemhepo ichiomesa uye dhizaini yemotokari inoshanduka, tekinoroji yewelding tekinoroji icharamba iri dombo repakona rekuvandudza, kutyaira indasitiri yemotokari kuenda kune remangwana rakajeka, rakachena.

Kune vanogadzira marobhoti emaindasitiri, kusimbisa kugona uku mukupedza pombi yekushandisa haingoratidzi hunyanzvi hwehunyanzvi asiwo inoisa mhinduro dzavo sevabatsiri vakakosha mukusimudzira kugona kugadzira mota.

Nguva yekutumira: Mar-21-2025