TIG welding Robot

Product Sumo

GTAW inonyanya kushandiswa kupinza zvikamu zvitete zvesimbi isina simbi uye isiri-ferrous simbi sealuminium, magnesium, uye alloys emhangura. Maitiro acho anopa mushandisi kutonga kukuru pamusoro peiyo weld pane kukwikwidza maitiro senge akavharidzirwa simbi arc welding uye gasi simbi arc welding, ichibvumira kune akasimba, emhando yepamusoro welds. Nekudaro, GTAW yakawedzera kuomarara uye yakaoma kugona, uyezve, inononoka zvakanyanya kupfuura mamwe akawanda maitirwo ewelding. Maitiro ane hukama, plasma arc welding, inoshandisa mwenje wakasiyana wakasiyana kugadzira arc inotarisisa welding uye semhedzisiro inowanzoita otomatiki.

Yunhua shandisa matanho ekudzivirira akakosha panguva yeTIG welding, uye pachava nebhuku rakakosha remushandisi, chete kana mutyairi anogona kutevera bhuku racho, uye kudzidzira kakawanda, inogona kukurumidza kukurumidza.

PRODUCT PARAMETER & DETAILS

| Model | WSM-315R | WSM-400R | WSM-500R | |

| Rated input voltage / frequency | Nhatu-chikamu380V (+/-)10% 50Hz | |||

| Yakatemerwa kuisa simba (KVA) | 11.2 | 17.1 | 23.7 | |

| Yakayerwa yekupinda ikozvino (A) | 17 | 26 | 36 | |

| Yakatemerwa kutakura mutoro (%) | 60 | 60 | 60 | |

| DC uye inogara iripo | Welding Curren (A) | 5~315 | 5-400 | 5-500 |

| DC pulse | Peak current (A) | 5~315 | 5-400 | 5-500 |

| Base current (A) | 5~315 | 5-400 | 5-500 | |

| Pulse basa (%) | 1-100 | 1-100 | 1-100 | |

| Pulse frequency (Hz) | 0.2~20 | |||

| TIG | Arc kutanga ikozvino (A) | 10~160 | 10~160 | 10~160 |

| Arc kumira ikozvino (A) | 5~315 | 5-400 | 5-500 | |

| Nguva yezvino-kuwedzera (S) | 0.1~10 | |||

| Nguva yezvino-kuderera (S) | 0.1~15 | |||

| Pre-kuyerera nguva (S) | 0.1~15 | |||

| Kunonoka nguva yekumisa gasi (S) | 0.1~20 | |||

| Nzira yekushanda yearc inomisa ikozvino | Matanho maviri、Matanho mana | |||

| TIG mutyairi arc maitiro | HF arc | |||

| Ruoko arc welding Welding ikozvino | 30~315 | 40-400 | 50-500 | |

| Kutonhodza mode | Kutonhora kwemvura | |||

| Shell kudzivirira giredhi | 1P2S | |||

| Insulation giredhi | H/B | |||

Application

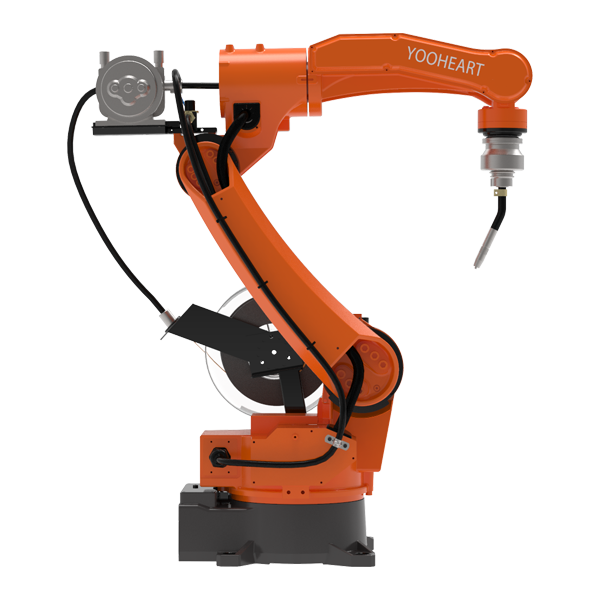

MUFANANIDZO 1

Nhanganyaya

Tig welding robhoti reMagetsi Iron

Pulse Tig welding process yehove scale weld seam.

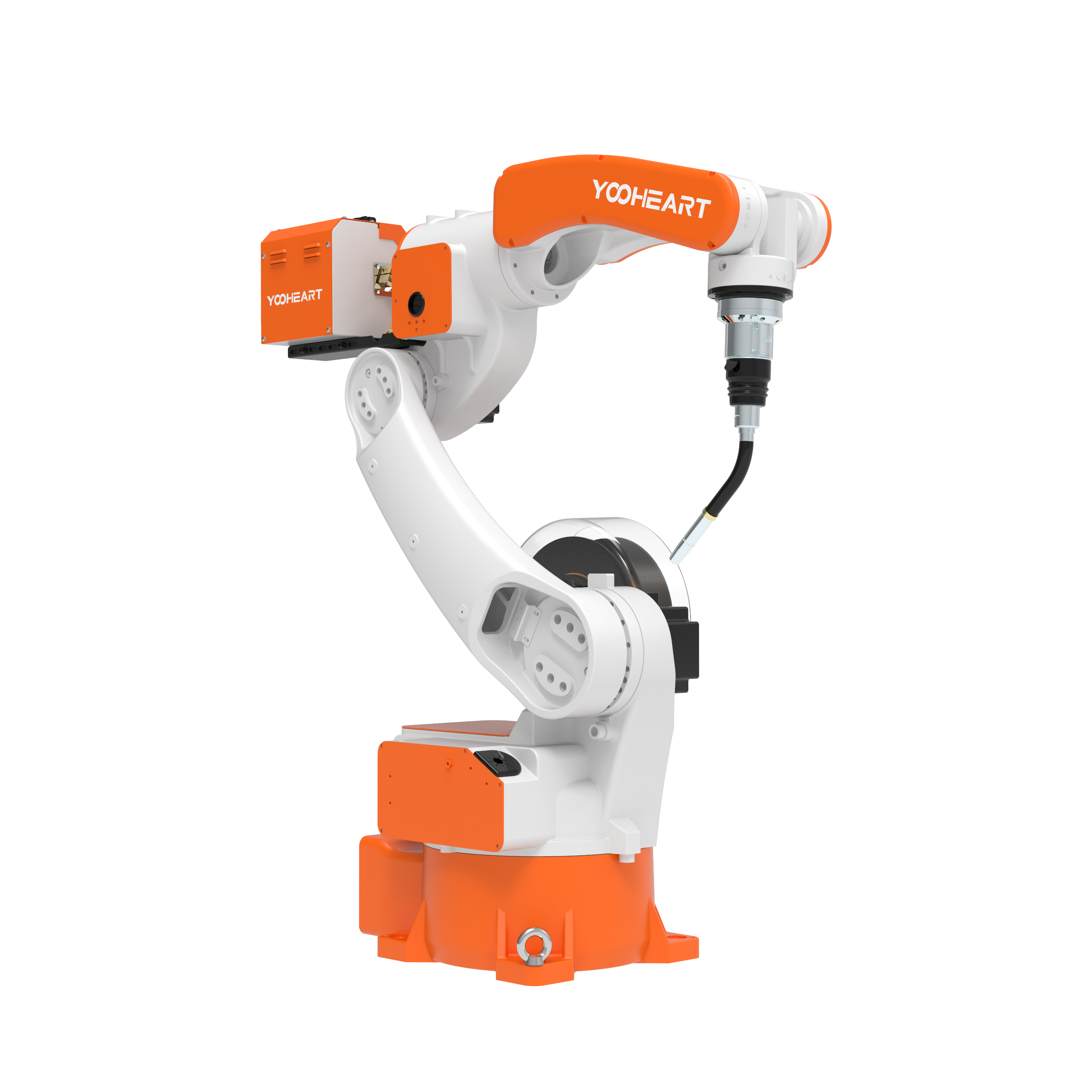

MUFANANIDZO 2

Nhanganyaya

Tig welding robhoti yeStainless simbi

Tig arc welding for square pombi welding.

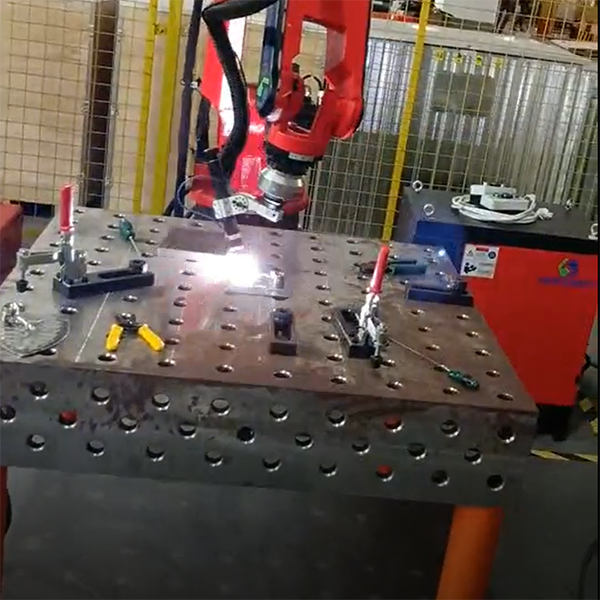

MUFANANIDZO 3

Nhanganyaya

Parameters yeTIG welding welder

Pulse Tig welding performance. Ukobvu: 1.5mm, kukanganisa kwakakodzera: ± 0.2mm.

KUSVIRA UYE KUTUMIRA

Yunhua inogona kupa vatengi nemashoko akasiyana ekutumira. Vatengi vanogona kusarudza nzira yekutumira negungwa kana nemhepo zvinoenderana nekukurumidzira kwekutanga. YOO HEART marobhoti ekurongedza makesi anogona kusangana negungwa nemhepo zvinotakura zvinhu. Tichagadzirira mafaera ese sePL, chitupa chekwakabva, invoice uye mamwe mafaera. Pane mushandi ane basa guru nderekuti marobhoti ese anogona kuendeswa kune vatengi chiteshi pasina kurova mumazuva makumi mana ekushanda.

Mushure mekutengesa sevhisi

Wese mutengi anofanira kuziva YOO HEART robhoti yakanaka vasati vatenga. Kana vatengi vaine imwe YOO HEART robhoti, mushandi wavo achave ne3-5 mazuva emahara kudzidziswa muYOO HEART fekitori. Pachave neboka reWechat kana boka reWhatsApp, ma technicians edu anotarisira mushure mekutengesa sevhisi, magetsi, hard ware, software, nezvimwe, zvichave mukati. Kana dambudziko rimwe rikaitika kaviri, technician yedu ichaenda kune vatengi kambani kugadzirisa dambudziko.

FQA

Q1. Ndeapi akanakisa kunyorera erobhoti TIG welding system?

A. High-volume, yakaderera-yakasiyana-siyana zvikumbiro zvakanyatsokodzera kune robotic welding; zvisinei, yakaderera-vhoriyamu, yakakwirira-yakasiyana-siyana maapplication anogonawo kushanda kana akaiswa neiyo tooling yakakodzera. Makambani anozoda kufunga nezve yakawedzerwa mutengo wekushandisa kuona kana irobhoti welding system inogona kuramba ichipa kudzoka kwakasimba pakudyara kwekutanga. Kana iri TIG welding, yakanakisa application zvimedu zvitete uye simbi.

Q2. Ndeipi inoshandisa zviri nani? HF TIG welding kana Simudza TIG welding?

A. Inonyanya kufarirwa uye yakanakisa sarudzo ndeye kushandiswa kweHigh Frequency kutanga iyo inogadzira yakakwira frequency arc inokwanisa kuita ionizing mhepo uye kuvhara mukaha pakati petungsten point nebasa. Iyo Yekumusoro Frequency kutanga inzira yekubata-ishoma uye inogadzira kunenge kusvibiswa kunze kwekunge tungsten yanyanya kurodzwa kana amperage yakadzoserwa zvakanyanya pakutanga. Iyo isarudzo yakanakisa yewelding aluminium, uye zvechokwadi ndiyo yega sarudzo inogamuchirwa. Kunze kwekunge iwe uchida weld Aluminium, haufanirwe kunge uine Yekumusoro Frequency kutanga, asi zvakanaka kuve ne weld AC kana DC kana uine sarudzo.

Q3. Unogona YOO HEART TIG welding robhoti kushandisa filler?

A. Hongu, isu tiri vamwe vevashoma vanogona kushandisa filler kana TIG welding. Vazhinji vatengesi pamusika vanogona kukuudza kuti marobhoti avo anogona kushandiswa TIG welding, unogona kumubvunza mibvunzo yakaita senge: sei kusefa HF?, Robhoti yako inogona kushandiswa TIG welding ne filler?

Q4. Maitiro ekuseta simba sosi kana uchishandisa TIG welding?

A. Your welding machine inofanira kuiswa kuDCEN (Direct current electrode negative) inozivikanwawo seyakatwasuka polarity kune chero chidimbu chebasa chinoda kuiswa weld kunze kwekunge zvinhu zviri aruminiyamu kana magnesium. Yakakwirira frequency yakagadzirirwa kutanga iyo inowanikwa yakavakirwa mumazuva ano muma inverters. Kuyerera kweposi kunofanirwa kusetwa kanenge masekonzi gumi mashoma. Kana A/C iripo inoiswa kune default setting inoenderana neDCEN. Seta iyo yekubatisa uye amperage switch kune kure kusetting. Kana zvinhu zvinoda kuiswa welded zviri aluminium polarity inofanira kuiswa kuA/C, A/C balance inofanira kuiswa kusvika pa7 uye high frequency supply inofanira kuramba ichienderera mberi.

Q5. Maitiro ekuseta nhovo Gasi panguva yeTIG welding?

A. TIG welding inoshandisa gasi inert kudzivirira nzvimbo yewelding kubva pakusvibiswa. Saka iyi gasi inert inonziwo inodzivirira gasi. Pazviitiko zvese inofanirwa kunge iri argon uye hapana imwe inert gasi senge neon kana xenon nezvimwe kunyanya kana TIG welding ichizoitwa. Inofanira kusetwa kutenderedza 15 cfh. Pakupisira aluminium chete unogona kushandisa 50/50 musanganiswa weargon nehelium.