Robotic Mig welding -----Mugwagwa Mwenje Pole welding mhinduro

Index

1. Mashoko echidimbu chebasa

2. Robotic welding Solution Overview

3. Robotic welding Solution Process

4. Robotic mhinduro Equipment Configuration

5. Basa guru 6. Kuiswa kweEquipments

7. Kuiswa, Kutumwa uye Kudzidziswa

8. Tarisa uye Kubvuma

9. Zvinodiwa Nezvakatipoteredza

10. Warranty uye Mushure mekutengesa sevhisi

11. Delivery Yakanamirwa Documentation

Robotic welding Yekushandisa Vhidhiyo

1, Workpiece Ruzivo

-Welding waya Diameter: Ф1.2mm

-Welding process: gasi shielded welding / Mig welding

-Weld musono mhando: yakatwasuka mutsara mhando, Denderedzwa mhando

-Kudzivirira gasi:99% CO2

-Operation Method: manual kurodha uye kurodha, robhoti otomatiki welding

-Kugadzirisa Error:≤ 0.5mm

-Plate Cleaning :metallic luster inogona kuonekwa mu weld uyemukati mehupamhi hwehuviri hwehurefu hwe weld seam kumativi ose maviri

2, Robotic welding solution Overview

Kuti uvandudze kushanda zvakanaka, zvinoenderana nemamiriro chaiwo ebasa, Honyen fekitori ichapa seti yewelding robhoti yekushandira, iyo inogona kutsiviwa neyakasiyana maturusi kuti ienderane neyakasiyana zvigadzirwa.Nzvimbo yekushandira inoumbwa nerobhoti modhi: HY1006A-145 welding robhoti, welding magetsi sosi, yakakosha welding torch yerobhoti, magetsi ekudzora Kabhineti nemabhatani, mvura inotonhorera chiller, kaviri yekushanda chiteshi chinzvimbo, Tooling zvigadziriso, chengetedzo fenzi (optional) nezvimwe. zvikamu.

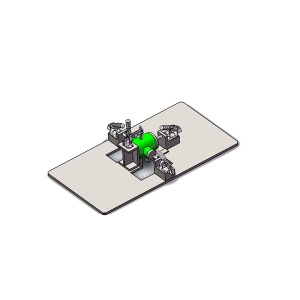

3, Mig Welding robhoti yekushandira Layout sumo

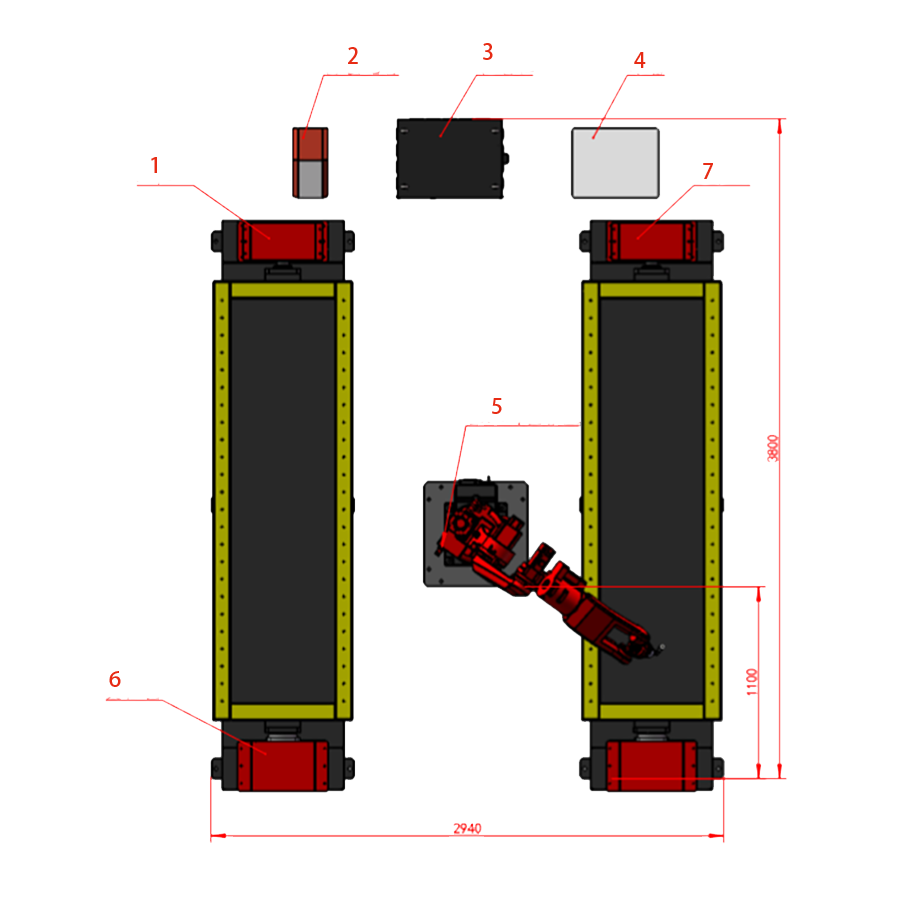

Honyen robhoti arc welding workstation Layout

1, Nzvimbo yekushanda 1

2, Welding Power sosi

3, Robot controller

4, Mvura inotonhorera chiller

5, Honyen arc welding Robot, HY1006A-145

6, Positioner

7, Chiteshi chekushanda 2

Zvigadzirwa zvemagetsi simbi

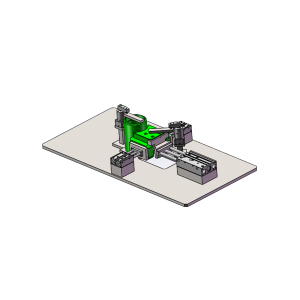

Magetsi mapale ezvigadziriso 2

Robhoti welding mhinduro Layout 1

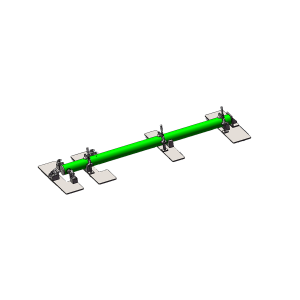

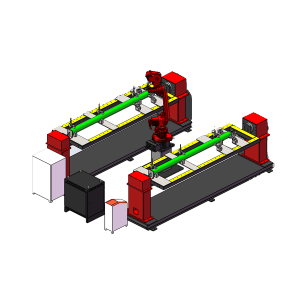

Magetsi Pole Zvikamu Zvigadziriso 3

Robhoti welding mhinduro Layout 2

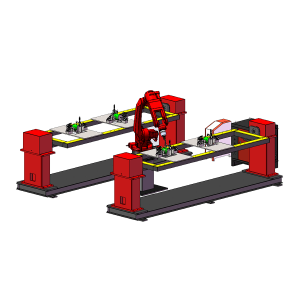

Robhoti welding mhinduro Layout 3

4. Robotic welding Solution Process I. Operator anoremedza workpiece pachiteshi 1, Mushure mekurodha uye nekuisunga.Operator anodzvanya robhoti reservation kutanga bhatani 1, uye robhoti inotanga otomatiki welding;

II.Operator inoenda kuchiteshi 2 yekurodha workpiece.Mushure mekurodha workpiece, Operator anodzvanya robhoti reservation kutanga bhatani 2 uye anomirira robhoti kupedza welding;

III.Mushure mekunge robhoti rapedza welding pachiteshi 1, rinobva raita chirongwa chechiteshi chechipiri;

Ⅳ.Ipapo Operator anoburutsa Workpiece pachiteshi 1 uye anorodha new workpiece;

V. kutenderera munhevedzano.

5. Robotic mhinduro Equipment Configuration

| Item | Model | Quantity | Brand | Mashoko | ||

| 1 | 1.1 | Robhoti muviri | HY1006A-145 | 1 Set | Honyen | Kusanganisira robhoti muviri, control cabinet, kudzidzisa programmer |

| 1.2 | Robot control cabinet | 1 set | ||||

| 1.3 | Welding simba Source | 1 Set | Honyen | Megmeet welder | ||

| 1.4 | tangi remvura | 1 Set | Honyen | |||

| 1.5 | Mvura inotonhorera welding Torch | 1 Set | Honyen | |||

| 2 | 1 Axis chinzvimbo | HY4030 | 2 Set | Honyen | 2.5m, 300kg mutoro, 1.5KW yakarongwa simba rekubuda | |

| 3 | Electrical control station | 2 Set | Honyen | |||

| 4 | Sistimu dhizaini, kusanganisa uye kuronga | 1 Set | Honyen | |||

| 5 | Safety fence | 1 Set | Honyen | Optional | ||

6. Basa guru Kuti ive nechokwadi chekushongedza uye kushanda zvakanaka, marobhoti sisitimu inoshongedzerwa neyakakwana yekuzvidzivirira basa uye arc welding dhatabhesi.Mabasa makuru ndeaya anotevera:

Tangazve nzira yepakutanga: kana shield gasi inoyerera isiri yakajairika, welding waya inopedzwa uye yakamira kwenguva pfupi panguva yewelding, murairo we "ramba uchipinza" unogona kudanwa zvakananga mushure mekugadzirisa matambudziko, uye robhoti inogona kuenderera mberi nekucheka kubva kune chero chinzvimbo kuenda kune yakamiswa chinzvimbo.

Kuona kukanganisa uye kufanotaura: mushure mekunge alarm yaitika, Robhoti inowana data kubva kumudziyo wekudzora, fungidzira zvikanganiso, uye inopa runyoro rwezvikamu zvakakanganisa zvakanyanya, kuratidza kutevedzana kwezvikamu zvekutsiva uye kuongororwa pakombuta, inogona kutariswa panzvimbo ine pendant yekudzidzisa.Uye zvakare, komputa inogara Iwana data rekushanda kubva kurobhoti, ongorora data rawanwa, tarisa kana mashandiro erobhoti akajairika, uye nekuchimbidza mushandisi kugadzirisa kukanganisa kuri kuuya.

Anti-kudhumhana basa: kana robhoti welding torch ikaita tsaona nezvinhu zvekunze, robhoti anti-collision mudziyo unoshanda kuchengetedza welding Torch uye robhoti muviri.

Nyanzvi database: nekuisa anodiwa welding mamiriro muchirongwa, iyi sisitimu inogona otomatiki kupedzisa kurongeka kwe weld seam uye kugadziridzwa kweanoenderana welding paramita.

Kudzidzisa uye purogiramu: ziva pane-saiti hurongwa kuburikidza nekudzidzisa pendant.

Weave welding: panguva welding muitiro, Robhoti haigoni chete kuziva zvakajairika swing welding kutenderera mhando uye Uyewo Z mhando.Izvi zvinobatsira robhoti kuona basa remutengi rekugezera zvinoenderana nebasa rechidimbu chimiro, kuitira kuti uwedzere weld seam hupamhi nesimba rekushongedza uye kuita kwakanaka kwewelding.

Status kuratidza: robhoti rinogona kuratidza mamiriro ekushanda kwerobhoti rese system kuburikidza nekudzidzisa pendant, kusanganisira chirongwa chekushanda, welding process parameter shanduko, system parameter shanduko, chinzvimbo chiripo cherobhoti, marekodhi enhoroondo yekuuraya, masaini ekuchengetedza, marekodhi earamu, nezvimwe, kuti vatengi vagone nenguva nzwisisa mamiriro erobhoti system uye kudzivirira matambudziko pamberi.

Kupinza / kubuda mafaira: marobhoti system mafaera uye mafaera echirongwa murobhoti system anogona kuchengetwa muSD kadhi mukati meRobhoti controller, uye zvakare inogona kuchengetwa kune ekunze michina.Zvirongwa zvakanyorwa ne-offline programming software zvinogonawo kuiswa muRobot controller, Izvi zvinobatsira vatengi kuchengetedza mafaira ehurongwa nguva dzose, Kana pane dambudziko murobhoti system, Aya backup anogona kudzoserwa kugadzirisa matambudziko erobhoti.

7, Nhanganyaya Equipments HY1006A-145 irobhoti repamusoro-soro rine basa rakangwara.Iyo yakakodzera gasi yakadzivirirwa welding uye yekucheka maapplication.Hunhu hwayo huremu huremu uye compact chimiro.

Kune arc welding application, Honyen yakabudirira kugadzira huremu huremu uye compact ruoko, iyo isingangovimbisi kuvimbika kwepakutanga, uye zvakare inoona yakanakisa mutengo kuita.

Honyen inotora yakanyanyisa servo tekinoroji, iyo inogona kuvandudza kufamba uye kurongeka kwerobhoti, kuderedza kupindira kweanoshanda, uye kunatsiridza kushanda zvakanaka kwegasi yakadzivirirwa welding nekucheka.

| Axis | Payload | Kudzokorora | Simba rakawanda | Environment | Kurema | Installation |

| 6 | 10 | 0.08 | 6.5KVA | 0~45℃20~80%RH(Hapana Humidity) | 300kg | Pasi/Ceiling |

| Motion Range J1 | J2 | J3 | J4 | J5 | J6 | IP level |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65 (ruoko) |

| Max kumhanya J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Yakazara Chinese oparesheni interface uye inogona kuchinjirwa muchiRungu ine yakazara keyboard kushanda

Tsigira kutaurirana kwakasiyana kunosanganisira I / O interface, Modbus, Ethernet nezvimwe.

Tsigira kubatanidza nemarobhoti akawanda uye zvimwe zvekunze zvishandiso

Saizi hombe ine mavara ekubata skrini

Yakagadzirirwa anti-collision mudziyo, inodzivirira robhoti ruoko uye inoderedza kupindira

Robot Motion control inopa yakakwana nzira kuronga

Mazana emabhegi ebasa akavakirwa-mukati uye mabasa anorerutsa hurongwa

Kuburikidza nekadhi reSD, zviri nyore kuchengetedza uye kukopa data

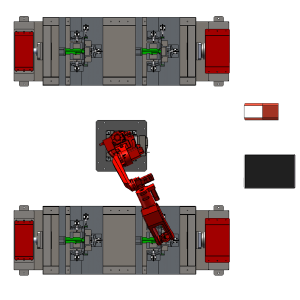

Positioner

Honyen Head-tail double support positioner iyo inoshandiswa kutenderedza workpiece, kushandirapamwe nerobhoti, inosvika pachinzvimbo chakanaka chewelding uye kuita zvakanaka welding.

Welding Power sosi

Megmeet Ehave masendimita 500h / 500 / 350 akatevedzana akazara dhijitari indasitiri inorema mutoro * CO2 / MAG / MMA akangwara welding muchina

8. Kuiswa, Kutumwa uye Kudzidziswa

Asati asununguka, iro robhoti system ichaunganidzwa uye inoshanda zvizere kuyedzwa mukambani yedu.Mutengi anoendesa zvikamu zvavo kukambani yedu yekuyedzwa welding uye pre-kugashira pamberi pekutakura.Panguva yekugamuchirwa, vashandisi veMutengi vanowana kudzidziswa kwehunyanzvi hwekutanga.

Kuisa chirongwa uye zvinodiwa zvehunyanzvi zvichaendeswa kune mutengi mazuva gumi nemashanu isati yaiswa, uye mutengi achaita gadziriro nenguva zvinoenderana nezvinodiwa.Kambani yedu inozotumira mainjiniya kuitisa sisitimu yekumisikidza uye kutumira panzvimbo yemushandisi.Pasi pemamiriro ekuti mutengi anovimbisa akakwana ekumisikidza workpieces, iyo nguva kubva pakumisikidzwa kwehurongwa, kudzidziswa kwevashandi kusvika kuhuwandu hwekuyedza kugadzirwa hakupfuure mazuva gumi.Kambani yedu inodzidzisa vashandisi marobhoti system programming, kushanda uye kugadzirisa kwevatengi, uye vanodzidzira vanofanirwa kuve neruzivo rwekombuta.

Panguva yekumisikidza uye kutumwa, mutengi achapa maturusi anodiwa, senge midziyo yekusimudza, forklift, tambo, kukanganisa kudhiraivha, nezvimwewo, uye kupa rubatsiro rwenguva pfupi panguva yekuburutsa nekuisa.

Kambani yedu ine basa rekutungamira, kuisirwa, kutumwa kwemidziyo uye kudzidziswa kweanoshanda.Kambani yedu ine basa rekuchengetedza uye kudzidzira kushanda.Operator achashanda uye chengetedza midziyo iri yega.Zvemukati zvekudzidzisa: dhizaini chimiro chemisimboti, yakajairwa magetsi kugadzirisa, sumo kune yekutanga hurongwa mirairo, hunyanzvi hwekuronga uye nzira dzekuronga dzezvakajairwa zvikamu, sumo uye dziviriro yemidziyo yekushandisa pani, mashandiro emidziyo, nezvimwe.

9. Tarisa uye kugamuchirwa

Pre-kugamuchirwa kunoitwa mukambani yedu nekubatanidzwa kwevashandi vakakodzera vemapato ese ari maviri.Panguva yekugashira-pre-kugamuchirwa, maworkpiece anozoyedzwa zvinoenderana nekurongeka kweworkpiece yakapihwa nemutengi, Chete chidhindo chebasa chinokwanisa kusungirirwa, uye pre-yekugamuchirwa bvunzo ripoti ichapihwa.Mushure mekupedzisira kugamuchirwa, Robhoti richaunzwa.Kuti uve nechokwadi chekugashirwa-pre-kugamuchirwa, 3 workpieces ichapihwa kune yakajairika kugadzirwa.

10.Zvinodiwa Nezvakatipoteredza Zvinodiwa zvekuchengetedza: gasi uye zvikamu zvakasara zvinoshandiswa nevashandisi zvinofanirwa kutevedzera zvinoenderana nenyika.

Mhepo ichaiswa kunze, isiri pasi pe15m kure nemoto, uye isiri pasi pe15m kure negasi neokisijeni.Mhepo inochengetedza mhepo yakanaka uye inogara munzvimbo inotonhorera kure nemhepo.

Yese magasi maseketi anofanirwa kutariswa usati washandisa robhoti.Kana paine kubuda kwemhepo, kunofanirwa kugadziriswa kuve nechokwadi kuti hapana chikanganiso.

pakugadzirisa kudzvinyirira uye kuchinja gasi cylinder, mufambisi haafaniri kuva nezvinhu zvemafuta pamaoko ake.

ambient humidity: kazhinji, iyo ambient humidity ndeye 20% ~ 75% RH (kana pasina condensation);Nguva pfupi (mukati memwedzi we1) isingasviki 95% RH (nguva dzisina condensation).

mhepo yakamanikidzwa: 4.5 ~ 6.0 kgf / cm2 (0.45-0.6mpa), mafuta esefa nemvura, ≥ 100L / min

Nheyo: shoma kongiri simba iC25, uye hushoma ukobvu hwenheyo ndeye 400 mm

vibration: gara kure kubva kuvibration source

magetsi: magetsi ezvese akagadzirwa emagetsi nemidziyo yemagetsi anotora 50Hz (± 1) uye 380V (± 10%) matatu-chikamu AC voltage kuve nechokwadi chekugadzika kwemagetsi.

Pasaiti masevhisi anopihwa nevatengi:

gadziriro dzose dzinodiwa dzisati dzasvika, dzakadai senheyo, basa rinodiwa rekugadzirisa, kugadzirisa zvishandiso zvekubatsira, nezvimwe.

kuburutsa uye kutakura panzvimbo yemutengi.

11. Warranty uye Mushure mekutengesa sevhisi Nguva yewaranti yeweld power source ndeye 12 mwedzi.

Nguva yewaranti yemuviri werobhoti ndeye 18 mwedzi.

Kana ikatadza kana kukuvadzwa pasi pekushandiswa kwakajairwa uye michina iri mukati menguva yewaranti, kambani yedu inogona kugadzirisa kana kutsiva zvikamu zvemahara EXW (kusingasanganisire zvinobatika, zvigadzirwa zvekugadzirisa, machubhu ekuchengetedza, marambi echiratidzo uye zvimwe zvinoshandiswa zvakasarudzwa nekambani yedu).

Kune zvikamu zviri munjodzi isina waranti, kambani yedu inovimbisa hupenyu hwesevhisi uye mutengo wekupa wezvikamu zviri munjodzi, uye michina ine yakagadzika nzira yekugovera yemidziyo kweanosvika makore mashanu.

Kunze kwenguva yewaranti, kambani yedu icharamba ichipa hupenyu hwese yakabhadharwa sevhisi uye nekupa yakazara tekinoroji rutsigiro uye inodiwa michina yemidziyo.

12. Delivery Attached Documentation Kugadzwa kudhirowa: dhizaini nheyo yekuvaka mifananidzo uye midziyo yekuisa mifananidzo

◆ dhizaini dhizaini: zvigadziriso uye dhizaini dhizaini

◆ Manual: chigadziro chekushandisa chigadzirisheni, bhuku rekugadzirisa uye robhoti rekushandisa bhuku

◆ accessories: rondedzero yekutumira, chitupa uye waranti kadhi.