Bingo TIG welding muchina

Titarise Pakuita!

Yakakurumbira Model Kutevera

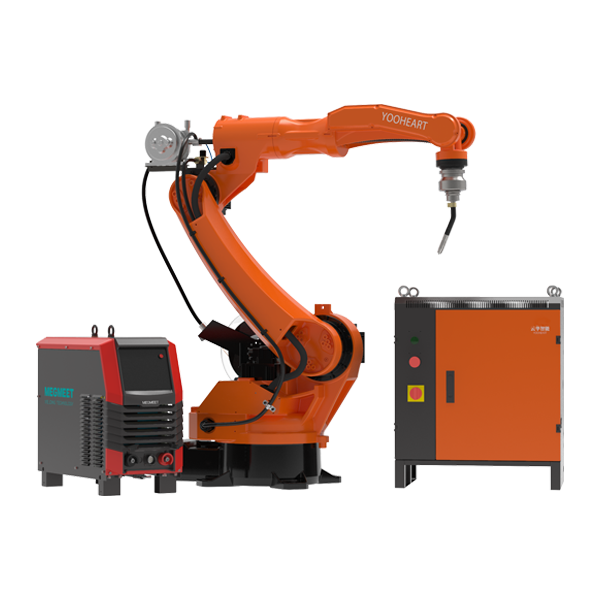

TIG welding Simba sosi, Manual & Robot modhi, Tsigira akasiyana kutaurirana protocal

WSME 315/400/500/630

Inverted AC uye DC pulse argon arc welding muchina

Mabasa:

AC inogara iripo TIG, AC pulse TIG, DC inogara iripo TIG, AC pulse TIG, manual mental-arc welding.

Indasitiri yekushandisa:

Aerospace, kupatsanurwa kwechadenga, indasitiri yepetrochemical, inotsinhanisa kupisa, fenicha yealuminium uye chiedza chebhasikoro.

Features:

Iyo pani yekushandisa ine dhizaini inonzwisisika, akapfuma mabasa uye nyore kushanda;

◆ The welding parameter inogona kugadzirirwa chaizvo;

◆ Iyo AC frequency uye yekuchenesa hupamhi inogona kugadziriswa yakazvimiririra kuti isangane nezvinodiwa zvewelding process yemhando dzakasiyana dzealuminium zvigadzirwa;

◆Ine nyore arc kurova, yakagadzikana yemagetsi arc uye nyore kudzorwa weld pool;

◆ Iyo argon arc welding inogona kudzivirira pfuti yekuputika kubva pakuderera kwemvura;

◆The welding current inogona kudzorwa kure;

◆ The weld kupinza uye weld hupamhi inodiwa ne weld joint uye nhamba ye waveform inogona kuwanikwa kuburikidza nekugadziriswa kwepulse ikozvino, impulse frequency, duty ratio, alternating current, AC frequency, kuchenesa chikamu uye AC bias ratio apo AC argon. arc welding inoshandiswa kurebesa hupenyu hwesevhisi, inonyanya kushanda kune otomatiki welding uye robhoti welding.

| Model | WSME- -315R | WSME-400 | WSME- 500 | WSME-630 |

| Rated input voltage / frequency | Nhatu-chikamu380V(+/-)10% 50Hz | |||

| Yakatemerwa kuisa simba (KVA) | 12.1 | 17.1 | 25.7 | 34.7 |

| Yakatemerwa yekupinda ikozvino (A) | 18.5 | 26 | 39 | 53 |

| Yakatemerwa kutakura mutoro (%) | 60 | 60 | 60 | 60 |

| Kubuda pasina-mutoro voltage (V) | 63 | 70 | 79 | 79 |

| Kubuda parizvino (A) | 5~315 | 5-400 | 20~500 | 20-630 |

| Arc kutanga ikozvino (A) | 10~315 | 10-400 | 20~500 | 20-630 |

| Peak current (A) | 5~315 | 10-400 | 20~500 | 20-630 |

| Arc kumira ikozvino (A) | 5~315 | 10-400 | 20~500 | 20-630 |

| Pre - kuyerera nguva (S) | 0.1~15 | |||

| Kunonoka nguva yekumisa gasi (S) | 0.1~20 | |||

| Pulse frequency (Hz) | 0.2~20 | |||

| Pulse duty (%) | 1-100% | |||

| AC frequency (Hz) | 20-200 | 20-200 | 20~100 | 20~100 |

| TIG mutyairi arc maitiro | HF arc | |||

| Kufambisa ikozvino (A) | 30-315 | 50-400 | 50-500 | 50-630 |

| Kutonhodza mode | Kutonhora kwemvura | |||

| Insulation giredhi | H/B | |||

WSM 315/400/500

Inverted DC pulse argon arc welding muchina

Mabasa:

DC inogara iripo TIG, DC pulse TIG, manual metal-arc welding.

Indasitiri yekushandisa:

Indasitiri yePetrochemical, ngarava yekumanikidza, kuvaka magetsi emagetsi, ngarava, bhasikoro, simba renyukireya uye pombi yekuisa.

Features:

◆Paneru yekushanda ine marongerwo anonzwisisika, mabasa akapfuma uye kushanda kuri nyore;

◆ Parameters yakadai sekunonoka kukwira uye kuderera kwemagetsi emagetsi, impulse frequency, duty ratio, nguva yekugadzirwa kwegasi yepamusoro uye gasi rakaputika rinogona kugadzirirwa zvakanyatsonaka;

◆ The manual metal-arc welding inogona kugadzirisa magetsi ekugadzirisa arc striking and thrust, nekurova kuri nyore kwearc uye kudzivirira kusungirirwa kwetsvimbo yekuputika;

◆ Iyo argon arc welding inogona kudzivirira pfuti yekuputika kubva pakuderera kwemvura;

◆Ine nhanho mbiri uye ina-nhanho welding control modes;

◆Iyo idiki uye yakareruka uye yakanakira kufamba;

◆ Ikozvino uye magetsi anogona kuratidzwa panguva imwe chete.Ikozvino welding inogona kugadzirirwa chaizvo;

◆TIG inogona kusarudza nzira yekusimudza frequency yearc inorova.

| Model | WSM-315 | WSM-400 | WSM-500 | ||

| Rated input voltage/frequency | Zvitatu-chikamu380V(+/-)10% 50Hz | ||||

| Yakatemerwa kuisa simba (KVA) | 11.2 | 17.1 | 23.7 | ||

| Yakatemerwa yekupinda ikozvino (A) | 17 | 26 | 36 | ||

| Yakatemerwa kutakura mutoro (%) | 60 | 60 | 60 | ||

| DC inogara iripo Welding ikozvino (A) | 5~315 | 5-400 | 5-500 | ||

| DC pulse | Peak current (A) | 5~315 | 5-400 | 5-500 | |

| Base current (A) | 5~315 | 5-400 | 5-500 | ||

| Pulse duty (%) | 1-100 | ||||

| Pulse frequency (Hz) | 0.2~20 | ||||

| TIG | Arc kutanga ikozvino (A) | 10~160 | |||

| Arc kumira ikozvino (A) | 5~315 | 5-400 | 5-500 | ||

| Pre-flow time (S) | 0.1-15 | ||||

| Kunonoka nguva yegesi- -kumisa (S) | 0.1~20 | ||||

| TIG mutyairi arc maitiro | HF arc | ||||

| Ruoko arc welding Welding ikozvino (A) | 30~315 | 40-400 | 50~500 | ||

| Kutonhodza mode | Kutonhodza mvura / Kutonhodza mhepo | ||||

| Shell kudzivirira giredhi | IP21S | ||||

| Insulation giredhi | H/B | ||||

WSM -S/YS 400

Inverted DC pulse argon arc welding muchina

| Model | WSM-400S/YS | ||

| Rated input voltage/frequency | Zvitatu-chikamu380V(+/-)10% 50Hz | ||

| Yakatemerwa kuisa simba (KVA) | 17.1 | ||

| Yakatemerwa yekupinda ikozvino (A) | 26 | ||

| Yakatemerwa kutakura mutoro (%) | 60 | ||

| DC inogara iripo Welding ikozvino (A) | 5-400 | ||

| DC pulse | Peak current (A) | 5-400 | |

| Base current (A) | 5-400 | ||

| Pulse duty (%) | 1-100 | ||

| Pulse frequency (Hz) | 0.2~20 | ||

| Pre-flow time (S) | 0.1-15 | ||

| Kunonoka nguva yegesi- -kumisa (S) | 0.1~20 | ||

| Maitiro ekushanda e arc anomisa ikozvino | Matanho maviri、Matanho mana | ||

| TIG mutyairi arc maitiro | HF arc | ||

| Kutonhodza mode | Kutonhodza mvura / Kutonhodza mhepo | ||

| Shell kudzivirira giredhi | IP21S | ||

| Insulation giredhi | H/B | ||

Mabasa:

DC inogara iripo TIG, DC pulse TIG.

Indasitiri yekushandisa:

Indasitiri yePetrochemical, ngarava yekumanikidza, kuvaka magetsi emagetsi, ngarava, bhasikoro, simba renyukireya uye pombi yekuisa.

Features:

◆Paneru yekushanda ine marongerwo anonzwisisika, mabasa akapfuma uye kushanda kuri nyore;

◆ Parameters yakadai sekunonoka kukwira uye kuderera kwemagetsi emagetsi, impulse frequency, duty ratio, nguva yekugadzirwa kwegasi yepamusoro uye gasi rakaputika rinogona kugadzirirwa zvakanyatsonaka;

◆ The manual metal-arc welding inogona kugadzirisa magetsi ekugadzirisa arc striking and thrust, nekurova kuri nyore kwearc uye kudzivirira kusungirirwa kwetsvimbo yekuputika;

◆ Iyo argon arc welding inogona kudzivirira pfuti yekuputika kubva pakuderera kwemvura;

◆Ine nhanho mbiri uye ina-nhanho welding control modes;Iyo idiki uye yakareruka uye yakanakira kufamba;

◆ Ikozvino uye magetsi anogona kuratidzwa panguva imwe chete.Ikozvino welding inogona kugadzirirwa chaizvo;

◆TIG inogona kusarudza nzira yekukwirira kwepamusoro kusimudza kwearc striking;

◆Iyo yakavakirwa-mukati yakasimba waya yekudyisa system ine hupfumi hwekuita mamenu ekudyisa waya, iyo inogona kusangana neyakasiyana nzira inodiwa;

◆Chiyero chekudyisa waya uye pulse current match otomatiki.

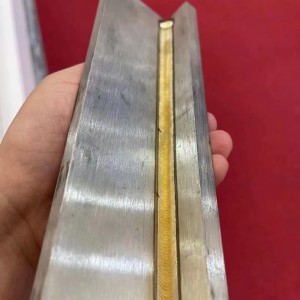

Kufunga nezve Welder

Kana mahwendefa maviri esimbi ane hukobvu hwakasiyana akabatanidzwa pamwe chete, kuitira kuti udzivise kushushikana kwakanyanya kunokonzerwa nekushanduka nekukurumidza kwechikamu chemuchinjiko, mupendero wendiro yakakora kazhinji inotetepa zvishoma nezvishoma kuti iwane ukobvu hwakafanana pamicheto miviri.Iyo static uye kuneta simba remagaro majoini akakwirira kupfuura mamwe majoini.Zvekubatanidza pasi pekuchinjana, mitoro yekuvhundutsa kana kushanda munzvimbo yakaderera tembiricha uye yakanyanya kudzvanywa midziyo, welding yemajoini emabutt inowanzodiwa.Iyo pre-welding yekugadzirira yejojo yemakumbo iri nyore, kuungana kuri nyore, uye iyo welding deformation uye yakasara kushushikana idiki, saka inowanzoshandiswa mukugadzika majoini uye zvisina kukosha zvimiro panzvimbo.Kazhinji, majoini emakumbo haakodzeri kushanda pasi pemamiriro akadai sekuchinjanisa mitoro, corrosive media, yakakwirira kana yakaderera tembiricha.Kushandiswa kweT-joints uye majoini emakona kazhinji kunokonzerwa nezvinodiwa zvemaitiro.Maitiro ekushanda asina kukwana fillet welds paT-joints akafanana nefillet welds pamakumbo majoini.Kana iyo weld iri perpendicular kune kutungamira kwekunze kwesimba, inova yekumberi fillet weld.Panguva ino, chimiro che weld pamusoro chinokonzeresa madhigirii akasiyana ekushushikana kushushikana;kushushikana kwekupinza fillet weld kwakafanana neiyo yebutt joint.

Sei Sarudza isu

TIRI VAKASIKA

BINGOinoramba ichitsvaga nekuvandudzaakangwara welding tekinorojiregai zvakawanda welding midziyokuenda pasi rose

TINE TINODA

Iye zvino zvakakanganiswa uye zvafarirwanenyika dzakawandamune ramangwana

TINOSHAMISA

Tichaisa mari yakawanda mukatiinoenderera r & d uye kugadziraEnda mberiusambomira