Megmeet Intelligent Digital Welding Machine

Megmeet Welder

Yakavakwa muna 2003

TOP 3 muChina

Megmeet Profile

MEGMEET

Mushandi:

3200+

R&D Engineers:

650+

100+

Partners

200+

Kubva kuHuawei & Emerson

12+

Classical Models

400+

Patents

8 R&D Centers

2 Manufacturing Bases

Mutengo Wakaderera Unoreva Mhindu Yakakwirira

- Kuchengetedza nenguva yakaderera. Nekuzvidzivirira dhizaini, masosi emagetsi acharatidza kodhi yekukanganisa pamamita. Kana zvikanganiso zvabviswa, sisitimu inodzokera kubasa seyakajairika. Kuputsika uye kuderera kuchadzivirirwa.

- Kuchengetedza nekushandiswa kwesimba kwakaderera. Kushandiswa kwesimba kwe7 KWH kunochengetwa mushure mekuisa tsvina yese yeMIG waya, zvichienzaniswa neye thyristor (SCR) welding machines.

- Kuchengetedza nekugona kusangana kwakasiyana ukobvu. Nokuda kwekubuda kwakasiyana-siyana ikozvino, welding performance inochengetwa pamwero unogutsa.

- Kuchengetedza nesoftware kuvandudzwa kweiyo welding process yakatarwa. Kana imwe welding process yakumbirwa, vashandisi vekupedzisira vanogona kukwidziridza iyo welding application software pachinzvimbo chekudyara mune itsva zvachose welding system.

- Saving thru welding quality control. Nekukiya-up basa, pane-saiti mamaneja eQC vanokwanisa kudzivirira chero shanduko isina kufanira yekumisikidzwa kwewelding nemawelder. Mutengo wekuongorora uchachengetwa zvakanyanya.

- Kuchengetedza kuburikidza neboka rekutonga system. SMARC, iyo boka rekutonga system, inokwanisa kubatanidza welding magetsi masosi ehuwandu hukuru kuMES. Mutengo wekutarisira uchachengetwa zvakanyanya kuburikidza nekutarisa iyo welding yakatarwa, kuburikidza nekuunganidza data uye kuongorora.

Tsanangudzo

| Manual | Ehave CM 500 H | Ehave CM 500 | Ehave CM 400 | Ehave CM 350 | Ehave CM250 |

| Robotics | Ehave CM 500 H AR | Ehave CM 500 AR | Ehave CM 400 AR | Ehave CM 350 AR | Ehave CM 250 AR |

| Kudzora Mode | Yakazara Digital-Kudzora | ||||

| Rated InputVoltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | ||||

| Input Frequency | 30 ~80 HZ | ||||

| Rated Input Power | 24 KVA | 22.3 KVA | 16.8 KVA | 13.5 KVA | 8 kVA |

| Simba Factor | 0.93 | 0.93 | 0.94 | 0.94 | 0.94 |

| Kubudirira | 86% | ||||

| Yakatemerwa OCV | 75 V | 73.3V | 63.7V | 63.7V | 63.7V |

| Rated Output Current | 30~500A | 30~500A | 30 ~ 400A | 30 ~ 400A | 30 ~ 400A |

| Rated Output Voltage | 12 ~ 45V | 12 ~ 45V | 12 ~ 38V | 12 ~ 38V | 12 ~ 38V |

| Duty Cycle | 500A 100% @ 40°C | 500A 60% @40°C390A 100% @40°C | 400A 60% @40°C310A 100% @40°C | 350A 60% @40°C271A 100% @40°C | 250A 100% @40°C190A 100% @40°C |

| Applicable Material | Carbon Steel | ||||

| WeldingProcess | CO2 / MAG/FCAW / MMA | ||||

| Wire Diameter | φ1.0/ 1.2/ 1.6 mm | φ0.8/ 1.0/ 1.2 mm | |||

| WeldingOperationMode | 2T / 4T / Yakadzokororwa 4T / Spot Welding | ||||

| ParameterChannel | 10 (Yakajairika) | ||||

| Inductance Scope (Yakanyorova / Yakasimba Arc) | -9~ +9 | ||||

| Kukurukuriranapamwe RobotController | Analogi | ||||

| ReservedKukurukuriranaInterface | CAN | ||||

| Cooling Mode | Intelligent Air Cool | ||||

| Kudyisa wayaSpeed | 1.4 ~ 24 m/min | ||||

| ElectromagneticKugarisana | IEC60974:10 EMS | ||||

| InsulationGiredhi | H | ||||

| IngressDziviriro | IP23S | ||||

| DziviriroAgainstLightening | Kirasi D (6000V/3000A) | ||||

| KushandaTembiricha &Humidity | -39°C~ +50°C; Humidity ≤ 95%; | ||||

| Dimension(L/W/H) | 620x 300 x 480 mm | ||||

| Gross Weight | 52 KG | 52 KG | 48 KG | 48 KG | 48 KG |

| Manual | Artsen Plus 500 D/P/Q | Artsen Plus 400 D/P/Q | Artsen Plus 350 D/P/Q |

| Robotics | Artsen Plus 500 D/P/QR | Artsen Plus 400 D/P/QR | Artsen Plus 350 D/P/QR |

| Kudzora Mode | Yakazara Digital-Kudzora | ||

| Rated Input Voltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | AC3PH 380V +/-25%(3PH 250V ~ 3PH 475V)AC 3PH 220V +/-15%(3PH 187V ~ 3PH 254V) | |

| Input Frequency | 45 ~ 65 HZ | ||

| Rated Input Power | 24 KVA | 22.3 KVA | 16.8 KVA |

| Simba Factor | 0.93 | ||

| Kubudirira | 87% | ||

| Yakatemerwa OCV | 85 V | ||

| Rated Output Current | 30 ~ 500 A | 30 ~ 500 A | 30 ~ 400 A |

| Rated Output Voltage | 12 ~ 45 V (Kururamisa pa 0.1V) | ||

| Duty Cycle | 500A / 39V 60% @ 40°C387A/ 33.5V 100% @ 40°C | 400A / 34V 100% @ 40°C | 350A / 33.5V 60% @ 40°C270A / 27.5V 100% @ 40°C |

| Applicable Material | D: Carbon Steel / Stainless SimbiP: Carbon Steel / Stainless SimbiMubvunzo: Carbon Steel / Stainless Steel / Aluminium Ally | ||

| Welding Process | D: MIG / MAG / CO2; Low- spatter;D: MIG / MAG / CO2; Low-spatter; Short-arc PulseMubvunzo: MIG / MAG / CO2;Low-spatter; Short-arc Pulse | ||

| Wire Diameter | φ0.8/0.9/ 1.0/ 1.2/ 1.6 mm | ||

| Welding Operation Mode | 2T/4T / Special 4T / Spot Welding / Leaping Welding | ||

| Inductance Scope (Yakanyorova / Yakasimba Arc) | -7~ +7 | ||

| Sunda-dhonza Torch Basa (1) | Ehe | ||

| Kukurukurirana neRobhoti Controller | Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNet/IP (2) | ||

| Digital Meter pane Wire-feeder | Ehe | ||

| Cooling Mode | Air Cool; Mvura Inotonhorera (Sarudzo) | ||

| Electromagnetic Compatibility | IEC60974:10 EMS | ||

| Insulation Grade | H | ||

| Ingress Dziviriro | IP 23S | ||

| Kudzivirirwa Kurwisa Mheni | Kirasi D (6000V/3000A) | ||

| Kushanda Tembiricha & Humidity | -39°C ~ +50°C; Humidity≤95%; | ||

| Dimension (L/W/H) | 620x 300 x 480 mm | ||

| Gross Weight | 52 KG | ||

| Manual | Artsen PM 500 F/N/AS/AD ll | Artsen CM 500 ll | Artsen PM 400 F/N/AS/AD ll | Artsen CM 400 ll |

| Robotics | Artsen PM 500 F/N/AS/AD R ll | Artsen CM 500 R ll | Artsen PM 400 F/N/AS/AD R ll | Artsen CM 400 R ll |

| Kudzora Mode | Yakazara Digital-Kudzora | |||

| Rated Input Voltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | |||

| Input Frequency | 30 ~80 HZ | |||

| Rated Input Power | 24 KVA | 22.3 KVA | 19.7 KVA/ 18KW | 15 KVA/12.7KW |

| Simba Factor | 0.93 | |||

| Kubudirira | 87% | |||

| Yakatemerwa OCV | 73.3 V | |||

| Rated Output Current | 30 ~ 500 A | 30 ~ 500 A | 30 ~ 400 A | 30 ~ 400 A |

| Rated Output Voltage | 12~45 V (Kururamisa pa 0.1V) | |||

| Duty Cycle | 500A 60% @ 40°C390A 100% @ 40°C | 500A 60% @ 40°C390A 100% @ 40°C | 400A 100% @ 40°C | 400A 100% @ 40°C |

| Applicable Material | F: Carbon SteelN:Kabhoni Simbi / Stainless SimbiAS/AD:Kabhoni Simbi /Stainless Simbi / Aluminium Alloy | Carbon Steel | F: Carbon SteelN:Kabhoni Simbi / Stainless SimbiAS/AD:Kabhoni Simbi /Stainless Simbi / Aluminium Alloy | Carbon Steel |

| Welding Process | VMIG/MAG/CO2Pulse MIG /MAGKaviri Pulse MIG / MAG | MIG / MAG/ CO2 | MIG/MAG/CO2Pulse MIG /MAGKaviri Pulse MIG/ MAG | MIG/ MAG/CO2 |

| Wire Diameter | φ0.8/ 1.0/ 1.2/ 1.6 mm | φ0.8/ 1.0/ 1.2 mm | ||

| Welding Operation Mode | 2T/4T / Special 4T / Spot Welding | |||

| Parameter Channel | 50 (Yakajairika) | |||

| Inductance Scope (Yakanyorova / Yakasimba Arc) | -9~ +9 | |||

| Sunda-dhonza Torch Basa (1) | Ehe | |||

| Kukurukurirana neRobhoti Controller | Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNetIP (2) | |||

| Digital Meter pane Wire-feeder | Ehe | |||

| Cooling Mode | Air Cool; Mvura Inotonhorera (Sarudzo) | |||

| Electromagnetic Compatibility | IEC60974:10 EMS | |||

| Insulation Grade | H | |||

| Ingress Dziviriro | IP 23S | |||

| Kudzivirirwa Kurwisa Mheni | Kirasi D (6000V/3000A) | |||

| Kushanda Tembiricha & Humidity | -39°C ~ +50C; Humidity ≤ 95%; | |||

| Dimension (L/W/H) | 620x300x480mm | |||

| Gross Weight | 52KG | |||

| Artsen CM 500C | |

| Kudzora Mode | Yakazara Digital-Kudzora |

| Mutakuri-Wave Kukurukurirana | High-speed Two-way Digital Carrier-wave Kukurukurirana |

| Rated Input Voltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) |

| Input Frequency | 30 ~80 HZ |

| Rated Input Power | 24 KVA |

| Simba Factor | 0.93 |

| Kubudirira | 86% |

| Yakatemerwa OCV | 75V |

| Rated Output Current | 50 ~ 500 A |

| Rated Output Voltage | 12 ~ 50 V (Kururamisa pa 0.1V) |

| Duty Cycle | 500A / 39V 100% @ 40°C |

| Applicable Material | Carbon Steel |

| Welding Process | CO2/MAG/FCAW/MMA |

| Wire Diameter | φ1.0/ 1.2/ 1.4/ 1.6 mm |

| Welding Operation Mode | 2T / 4T / Special 4T |

| Parameter Channel | 10 (Yakajairika) |

| Inductance Scope (yakapfava/ Yakasimba Arc) | -9~ +9 |

| Reserved Communication Interface | CAN |

| Cooling Mode | Air Cool |

| Digital Meter pane Wire- feeder | EHE |

| Wire-feeding Speed | 1.4~ 24 m/min |

| Electromagnetic Compatibility | IEC60974:10 EMS |

| Ingress Dziviriro | IP 23S |

| Insulation Grade | H |

| Kudzivirirwa Kurwisa Mheni | Kirasi D (6000V/3000A) |

| Kushanda Tembiricha | -39°C~ +50°C |

| Dimension (L/ W/ H) | 620x300x480mm |

| Gross Weight | 52 KG |

| Manual | Dex DM 3000 | Dex DM 3000 S | Dex PM3000 | Dex PM 3000 S |

| Robotics | - | Dex DM 3000 R | - | Dex PM3000 R |

| Kudzora Mode | Yakazara Digital-Kudzora | |||

| Rated Input Voltage | AC 3PH 380V -15%~ +21% (3PH 323V ~ 3PH 460V) | |||

| Input Frequency | 45 ~ 65 HZ | |||

| Rated Input Power | 9.2KVA/ 8.7 KW | |||

| Simba Factor | 0.94 | |||

| Kubudirira | 81% (210A/ 24.5V | |||

| Yakatemerwa OCV | 54.2 V | |||

| Rated Output Current | 280 A | |||

| Output Current Range | 30A~ 300A | |||

| Rated Output Voltage | 12 ~ 30 V (Kururamisa pa 0.1V) | |||

| Duty Cycle | 280A/ 28V 60% @ 40°C 217A / 24.9V 100% @ 40°C | |||

| Applicable Material | Carbon Simbi / Stainless Simbi | Carbon Simbi / Stainless Simbi / Aluminium Alloy | ||

| Welding Process | MIG/MAG/CO2/MMA | MIG/MAG/CO2/MMA Pulse MIG/MAG Kaviri Pulse MIG/MAG | ||

| Wire Diameter | 0.8/0.9/1.0/1.2 mm | |||

| Welding Operation Mode | 2T | 2T / 4T / Special 4T | ||

| Parameter Channel | 50 (Yakajairika)

| |||

| Inductance Scope (Yakanyorova / Yakasimba Arc) | -9~ +9 | |||

| Kukurukurirana neRobhoti Controller | - | Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNet/IP

| - | Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNet/IP

|

| Digital Meter pane Wire-feeder | - | Ehe | - | Ehe Mhando yakavharirwa ine digital mamita (A/ V) |

| Cooling Mode | Air Cool; Mvura Inotonhorera (Sarudzo) | |||

| Wire-feeding Speed | 1.4 ~ 28 m/min | |||

| Electromagnetic Compatibility | IEC60974:10 EMS | |||

| Insulation Grade | H | |||

| Ingress Dziviriro | IP 23S | |||

| Kudzivirirwa Kurwisa Mheni | Kirasi D (6000V/3000A) | |||

| Kushanda Tembiricha & Humidity | -40°C ~ +70°C ; Humidity≤95%; | |||

| Dimension (L/W/H) | 610x260x398mm | |||

| Gross Weight | 25.4 KG | 23.7 KG | 25.4 KG | 23.7 KG |

Mushandisi-ane hushamwari Dhizaini: iri nyore kushandisa

Nyore-Ku-Kushandisa Dhizaini kune Vasina Unyanzvi Welders

- Yakavakwa-mukati Basa reAnti-shake

- On / Off Sarudzo yeSynergi Control

- On/Off Sarudzo yekupinda nguva dzose

Kukiya-up Basa

- Pasina chero mudziyo wekunze, password yekuvhara inokwanisa kumisikidzwa pamberi pepaneru. Izvo zvakakumbirwa welding zvinotsanangurwa zvichadzivirirwa zvakanyanya kubva kune zvisina kufanira shanduko. Management uye yekuongorora mutengo uchadzikiswa, nepo welding mhando ichizove nechokwadi.

Kukurumidza Kudzoreredza Kwekugadzira

- Iyo yakamisikidzwa chimiro uye modular dhizaini inowedzera kuvimbika. Kubvisa uye kuunganidza zvakare kuchava pfupi munguva yekushandisa.

- Simba remagetsi rakagadzirirwa kuona kusagadzikana muhurongwa hwese. Kodhi yekukanganisa icharatidzwa, asi sosi yemagetsi haizokanganiswe.

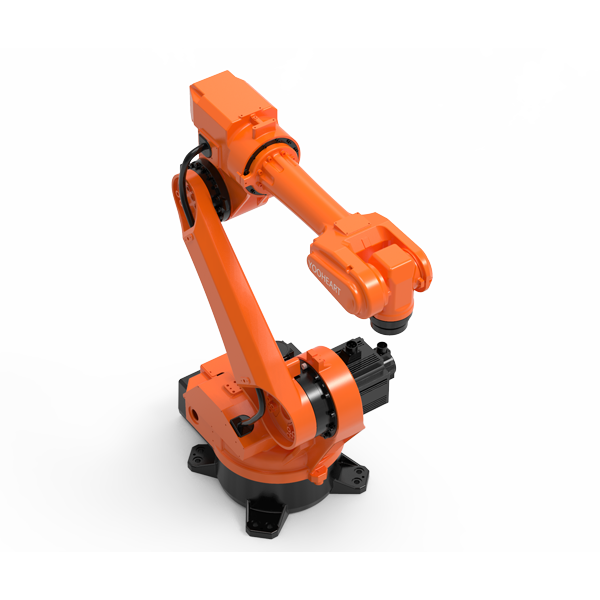

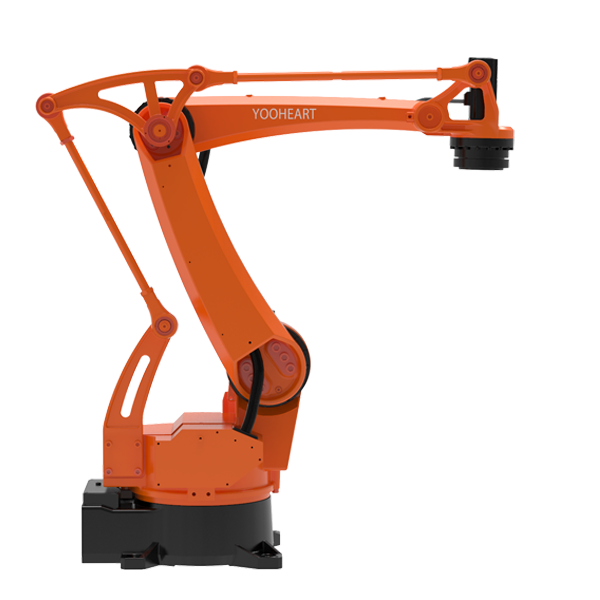

Robotic welder Zvishandiso

Honyen Robot Ine Megmeet weld muchina

Yooheart robhoti ine Megmeet digitaalinen weld simba sosi

Megmeet Mutengi