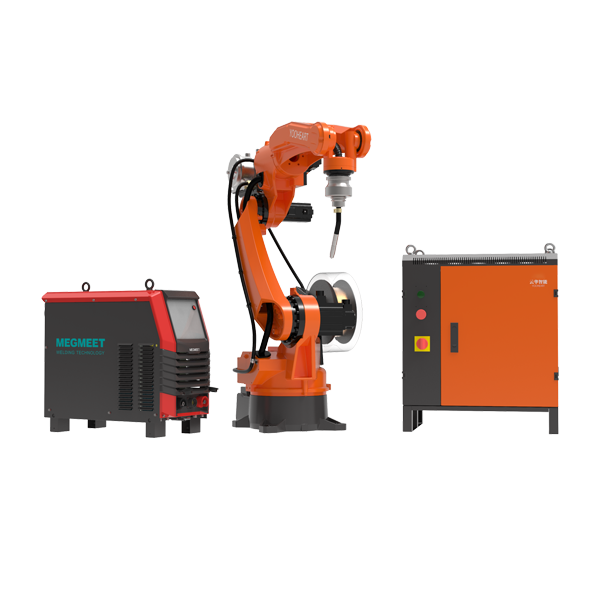

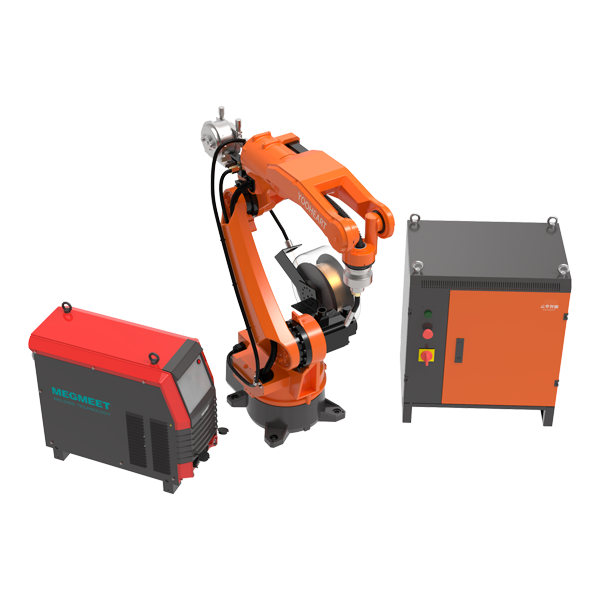

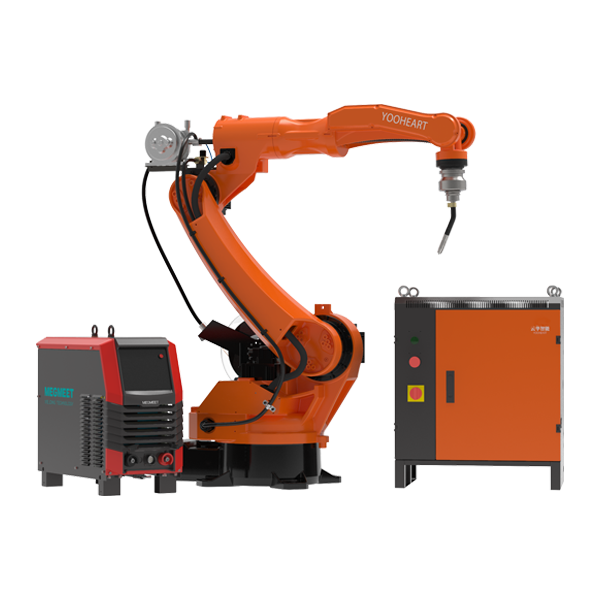

6 Axis Arc welding Robot 1450mm ruoko kureba NeMegmeet welding simba sosi

-Robhoti muviri: HY1006A-145

-Weld simba sosi: Megmeet Ehave CM 350AR

-Welding Torch: Loyee gasi kutonhora torch Kana Honyen Gasi kutonhora torch

-Waya feeder ine 0.8/1.0 waya roller

-LNC controller uye Panel

-Wooden Packing yekutumira kunze

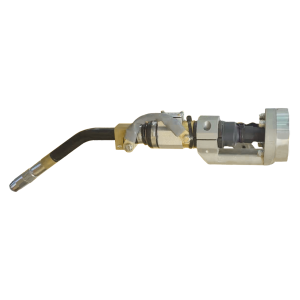

Optional Welding Torch

Loyee Robot Welding Torch

Yakakwira torque uye tambo yekupfeka inodzivirira

Invention patent yeAnti-collision tekinoroji

Kumhanya kukuru uye kurongeka chaiko kwe-anti-collision device\

Waya Dhiya: 0.8 ~ 1.0mm

Honyen Robot Welding Torch

Yakakwira torque uye tambo yekupfeka inodzivirira

Invention patent yeAnti-collision tekinoroji

Kumhanya kwepamusoro uye kurongeka kweiyo anti-collision mudziyo

Waya Dhiya: 0.8 ~ 1.0mm

Zvimwe Zvishandiso Zvekugadzirisa

Megmeet Ehave CM 350AR

| chinhu | Tsanangudzo |

| Model | Megmeet Ehave CM 350 |

| Voltage | 3*380V±25% 30--80HZ |

| Rated Input Power | 13.5KVA |

| Simba Factor | 0.94 |

| Kubudirira | 86% |

| Yakatemerwa OCV | 63.3V |

| Rated Output Current | 30A-400A |

| Rated Output Voltage | 12V-38V |

| Wire Dia | 0.8mm/1.0mm/1.2mm |

| IP Level | IP23S |

| Insulation Grade | H |

| Cooling Mode | Air Cooling |

| Dimension (L*W*H) | 620mm*300mm*480mm |

| Kurema | 48kg |

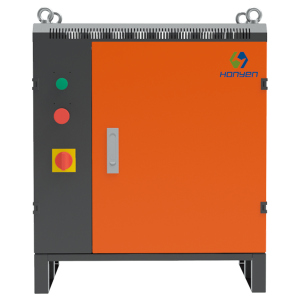

Kudzora Cabinet

| Item | Tsanangudzo |

| Cabinet size | 603mm*502mm*760mm |

| Kurema | 55kg |

| IP Level | IP54/IP65 |

| Tembiricha | Kushanda: 0-45 ℃Kuchengetedza: -10 ~ 60 ℃ |

| Humidity | Max 90% (Hapana-condensation |

| Voltage | 3*380V 50~60HZ |

| Kutonhodza System | Fan Cooling |

| Cable Length | Chiyero: 5M, Max:12M |

| Kukurukurirana Mode | Pulse |

Wire feeder

Timely Response Wire kudya uye shure

Kudyisa waya munyoro, Hapana-kuunganidza uye Kutsvedza

Yakasimba Anti-kupindira Capacity

Mutengi Application

Baby Carriage Robot Working Station

Steel Ladder Robot Kushanda Chiteshi

Mifananidzo PaMutengi Factory

Welding Robot Parameters

| Axis | Payload | Kudzokorora | Simba rakawanda | Environment | Kurema | Installation |

| 6 | 6kg | 0.08 | 6.5KVA | 0 ~ 45 ℃ 20 ~ 80% RH (Hapana Condensation) | 170kg | Pasi/Ceiling |

| Motion Range J1 | J2 | J3 | J4 | J5 | J6 | IP level |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65 (ruoko) |

| Max kumhanya J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Exibitions

Beijing Essen Welding & Cutting Fair

China International Indasitiri Fair - CIIF

China International Machine Tool Show

FQA

Q. Ndeipi musika wakakosha werobhoti yako?

A. Ikozvino robhoti redu rinogona kushandira mota, chimiro chesimbi, muchina wepurazi, fenicha yesimbi, simba idzva, kuchengetedza uye kutumira, muchina weinjiniya, midziyo yemuviri, muchina wemhuka, bhasikoro bhasikoro nezvimwe.

Q.rudzii rwesevhisi yaunogona kupa?

A. Kana ari maapplication, welding, handing, pick and place, paint, palletizing, laser cutting, laser welding, plasma cutting and so.

Q. Ndeupi rudzi rwewelding process yaunayo?

A. Nezve maapplication ewelding, tinogona kupa argon arc welding, mag welding, gasi shield welding, tig self fusion welding, tig wire feeding welding.

Q. Ndeipi mhando yemagetsi sosi yaunopa robhoti?

A. Iye zvino kune chiyero chekugadzirisa: Megmeet uye AoTai.

Q. Iwe une yako pachako hurongwa hwekutonga?

A. Hongu, hongu tine.Kwete chete isu tine control system, iyo inonyanya kukosha zvikamu zverobhoti: reducer iri kugadzirwa.Ndicho chikonzero isu tine mutengo wakanyanya kukwikwidza.

Mushure mekutengesa Service

Iyo chigadzirwa chemhando yevimbiso nguva igore rimwe kubva pazuva rekutumira.Kana robhoti remagetsi rikatadza panguva yewaranti (kunze kwekutadza kunokonzerwa nekushandiswa zvisina kunaka nemutengi), Honyen Robot ndiye achange aine basa rekuchengetedza kusvika atsiva mudziyo mutsva (EXW), uye mari inobhadharwa ichatakurwa naHonyen (muripo wekutumira). haina kubatanidzwa);Muchiitiko chekutadza kwemidziyo yakakonzerwa nekushandisa zvisirizvo kwemutengi, Honyen fekitori ichave nebasa rekugadzirisa uye kubhadharisa kutsiva zvikamu.

Munguva yewaranti, kana zvikaitika kutadza kwemidziyo, mutengesi wehunyanzvi hwebasa revashandi vanogadzirira maturusi anodiwa uye zvikamu zvakasara mukati memaawa masere mushure mekusimbisa kutadza kwemidziyo nevashandi vepa-saiti uye kugadzirisa vashandi, uye vasvike panzvimbo mukati maawa makumi maviri nemana. tanga kugadzirisa, kugadzirisa matambudziko (kunze kwechikonzero chedaro).

Gore rega rega, zvichienderana nemamiriro chaiwo emusika uye zvinodiwa nevashandisi vedunhu, kambani inogara ichiita zvematunhu tekinoroji yekudzoka kushanya pasina muripo (kunze kwemubhadharo webasa wekutsiva zvikamu uye zvikamu).

Zvinoenderana nezvigadzirwa zvinotengeswa nekambani yedu uye zvakajairwa zvikamu uye zvikamu zvinodyiwa zveseti yakazara yewelding robhoti, isu tinovimbisa kupa akajairwa masevhisi.Izvo zvakasara zviri mudura (kunze kwezvigadzirwa zvakakosha).Zvikamu zvakajairwa uye zvinodyiwa zvinovimbiswa kupihwa nenguva zvichienderana nekurongeka, uye zvikamu zvakakosha zvinoodha zvinoenderana nechibvumirano chakabvumiranwa nemapato ese.

Mushure mekupera kwenguva yewaranti, kana michina ikatadza, Mutengesi acharamba achipa masevhisi ekugadzirisa kumutengi, kubhadharisa mutengo wekutsiva zvinhu, uye kubhadharisa mari yebasa rekutanga rebasa repaimba neimba.

Zvinoenderana nezvinodiwa nemutengi, Mutengesi ndiye achave nebasa rekusimudzira kweupenyu hwese kwesoftware yemidziyo inoshandiswa nemutengi weMig welding robhoti.