Iko kushandiswa kwemarobhoti ekushivirira kunofanirwa kunyatso kudzora kunaka kwegadziriro yezvikamu uye kuvandudza kurongeka kweungano yeweldments.Hunhu hwepamusoro, saizi yegroove uye kurongeka kwegungano kwezvikamu kuchakanganisa iyo welding seam yekutevera maitiro.Unhu hwekugadzirira kwezvikamu uye kururamisa kwekusangana kwe weldment kunogona kuvandudzwa kubva pane zvinotevera.

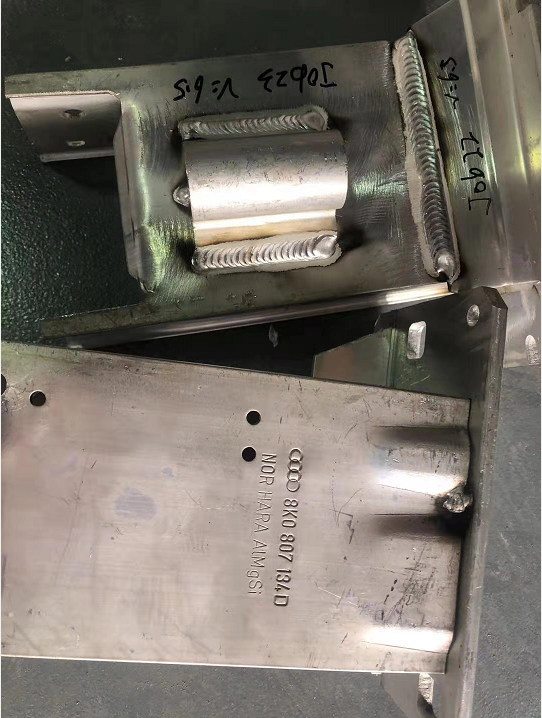

(1) Unganidza yakakosha welding process yewelding marobhoti, uye gadzira yakasimba process mirau pahukuru hwezvikamu, weld grooves, uye zviyero zvemagungano.Kazhinji, kushivirira kwezvikamu uye kukura kwegorofu kunodzorwa mukati me ± 0.8mm, uye kukanganisa kwegungano kunodzorwa mukati me ± 1.5mm.Iko mukana wekuremara kwewelding senge pores uye undercuts mu weld inogona kuderedzwa zvakanyanya.

(2) Shandisa yakakwirira-chaiyo dhizaini yekubatanidza kuti uvandudze kurongeka kwegungano kweweldments.

(3) Welding seams inofanira kucheneswa, isina mafuta, ngura, welding slag, kucheka slag, nezvimwewo, uye solderable primers inobvumidzwa.Zvikasadaro, zvinokanganisa mwero wekubudirira kwearc ignition.Tack welding inoshandurwa kubva kumagetsi emagetsi kuenda kune gasi yakadzivirirwa welding.Panguva imwecheteyo, nzvimbo dzekushongedza dzakakwenenzverwa kudzivirira kusara kwe slag crusts kana pores nekuda kwetack welding, kuitira kudzivirira kusagadzikana kwearc uye kunyange spatter.

Nguva yekutumira: Sep-11-2021